The new AlN heater from hotset is designed for the extremely rapid heating and cooling of gases and liquids in demanding high-tech applications in the semiconductor, medical, automotive and aerospace industries.

The thermodynamics specialist hotset is expanding its range of heating elements with the new Hi-Watty Light aluminum nitride heater, an exceptionally powerful premium product. Designed for high-speed heating and cooling of gases and liquids, this compact ceramic heater is the perfect solution for sophisticated high-tech applications in semiconductor and medical technology, as well as in the automotive and aerospace industries.

The efficiency of many fluid technology processes and devices is predominantly based on the fact that the gases or liquids carried in pipes and containers can be heated up and cooled down very quickly. By including the aluminum nitride heater Hi-Watty Light in its component portfolio, hotset now offers a top-class heating element for this task, which both enables ultra-fast heating processes and ensures a very homogeneous heat distribution. As such, product developers and technical buyers in the semiconductor, medical, automotive and aerospace industries, for example, now have access to an innovative and highly efficient alternative to silicone, polyimide or mica heating elements. “Our new ceramic heater is of particular interest to users who adopt particularly innovative approaches in the development and optimization of solutions for thermal management or medium temperature control,” says Key Account Manager Daniel Honsel. Specifically, the Hi-Watty Light is used in applications such as automated semiconductor test systems for automotive engineering or in the context of flip-chip assembly, a high-tech process for contacting microelectronic elements without a housing.

Hi-Watty Light from hotset features a very high thermal conductivity of 180 W/m • K (or higher) – similar to that of metallic aluminum – as well as excellent power density and thermal shock resistance. Its exceptionally compact design means that it requires only minimal installation space. Installation is not subject to any special requirements. Its thermal expansion rate is just 4.8 x 10-6/ °C and the contact resistance at room temperature (25 °C) is 2.6 x 1014 Ω • cm. Daniel Honsel also emphasizes that ” the AlN heater is a genuine hidden champion and hotset is one of the few suppliers in Europe to have such a tiny but powerful ceramic heater in its product range”.

Four ready-to-install variants

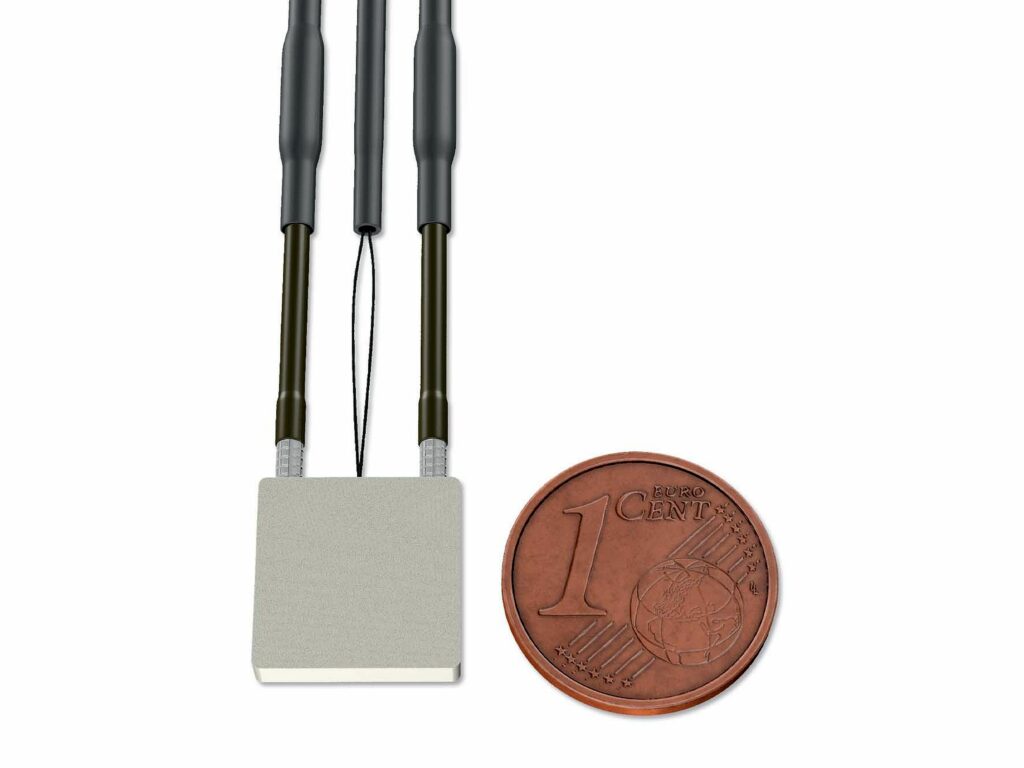

hotset offers the new AlN heater in four standard versions for voltages from 100 to 200 volts, which differ in their dimensions and technical parameters. The sizes, including the cables, vary from 12 x 2.5 mm to 50 x 2.5 mm, the outputs from 45 to 1,600 watts, the power densities from 16 to 96 W/cm2 and the resistance values from 25 to 400 Ω. What all variants have in common is the design for a maximum operating temperature of 400 °C and the construction consisting of a ceramic heating plate with two current-carrying lines and a signal cable running between them for connecting measuring and control systems. The AlN heater is always delivered ready for installation on surfaces or for introduction into pipes and process vessels carrying media. “Also worth mentioning is that this heater has high-quality electrical insulation and is highly resistant to corrosion,” adds Daniel Honsel.

The new AlN heater by hotset features a very high thermal conductivity of 180 W/m — K (or higher) and requires only minimal installation space due to its exceptionally compact design.

Faster, smaller, lighter

By adding an above-average responsive ceramic heater in miniature format to its range of heating elements, hotset is clearly responding to two current technology trends in the development of modern heat management and temperature control systems for gases and liquids: For one thing, the growing need for very fast and efficient heating and cooling processes; for another, the requirement to make the dimensions of technical units, modules or devices ever lighter and smaller in the context of miniaturization.