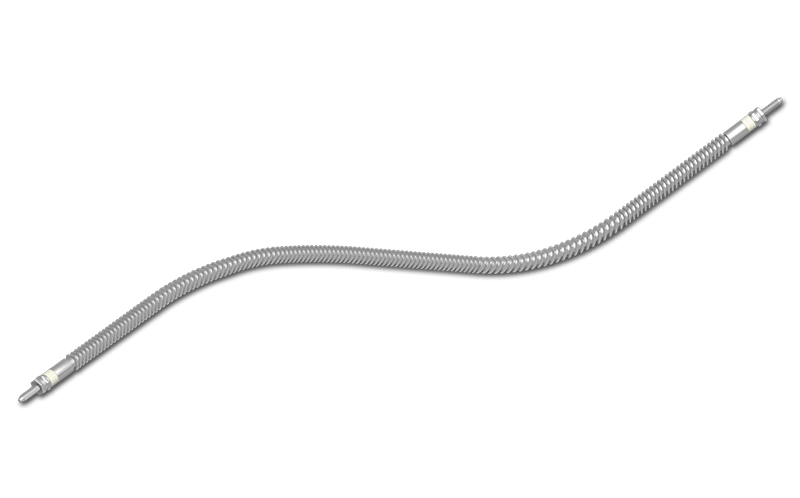

Bendable by hand in all three dimensions

hotflex Flexible Tubular Heaters

The hotflex is the world’s first tubular heater that can be bent freely by hand in all three dimensions. Simplified handling, easy assembly, optimum thermal properties and simplified stock-keeping (the hotflex is supplied stretched in numerous lengths from stock) are the outstanding product arguments.

hotflex Flexible Tubular Heaters

The three-dimensional bendability of the hotflex provides designers with a high degree of “application flexibility” compared to traditional heating (e.g. with hotrod heating cartridges type HHP).

For applications such as contour heating, in addition to the improved heat transfer, considerable savings can be achieved in terms of tool mass, spare parts procurement and lower energy consumption.

And this is possible in both round (Ø 6.5 mm and 8.5 mm) and square (6 x 6 mm and 8 x 8 mm) shapes.

Stock Range

You can view our wide range of bearings in our brochure in the download area (starting on page 4). Please enquire about our stock range using our standard inquiry form.

hotflex Extension Factors

Depending on the number of bending radii, the hotflex becomes longer when bending and pressing in. For a more precise calculation of the stretching you can use our template.

Construction and mounting

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von YouTube.

Mehr erfahren

A successful product finds imitators

In some countries there are already manufacturers who try to copy our hotflex.

To ensure that you have received and are using original hotset heaters, we have put together some tips to help you distinguish our hotflex from other products that claim to be a hotset hotflex.

Identify an Original hotflex from hotset:

Marking

Hotflex heaters are marked with our name “hotset”, with the electrical voltage and power. Production data can be traced via an additional number.

Each heater is marked with “CE”

Material

The surface of a hotflex is made of stainless steel. It is completely closed. There is no brass, copper, metal braid, metal link tubing or similar variations on the outside.

Surface texture

The stainless steel cover is completely closed and without interruptions. It looks somewhat like rings joined together. These are not spirals, but closed rings, see the picture.

Since the heater is highly compressed, the jacket can not move and detach from the heater.

The bending behavior

Although the hotflex is highly compressed and made of stainless steel, it can be easily bent by hand – without much force or even special tools. This is one of the unique advantages due to the patented manufacturing process that our customers appreciate over other heating elements.

Why use the original?

Quality and safety – temperature makes the difference

Some other so-called “flexible heating elements” offer sufficient electrical values when cold. However, when heating up, the raw material used, the manufacturing technology and the overall quality then determine the electrical safety of the heating element.

Quality

The hotflex achieves its excellent heat transfer due to its high density nature and patented technology. You can achieve perfect heat transfer for round and square hotflex by following our recommended groove geometry. For example, with a groove width of 8.2 mm for a hotflex with a diameter of 8.5 mm, the heater deforms and compresses during installation in such a way that there is hardly any space for air gaps and the heater surface contacts the mold from one groove edge to the other with pressure.

The illustration shows the hotflex driven in with a plastic hammer — without hydraulic pressing or other post-processing.

This means for you:

- Excellent heat transfer

- Reliability

- Short heat-up times

Safety

The hotflex is developed and manufactured according to German and European standards and laws. This means high reliability and safety for you and your employees – meaning for example:

- High voltage resistance

- Isolation resistance

- Leakage current

What does this mean?

In the event of an electrical defect on a machine, a poor quality heater can cause electrical voltages on the machine surface.

This can become a hazard to the health and life of your employees. An electrical defect could occur on any machine, especially if parts move or temperature changes occur.