High-precision platinum sensors for medical and dental technology

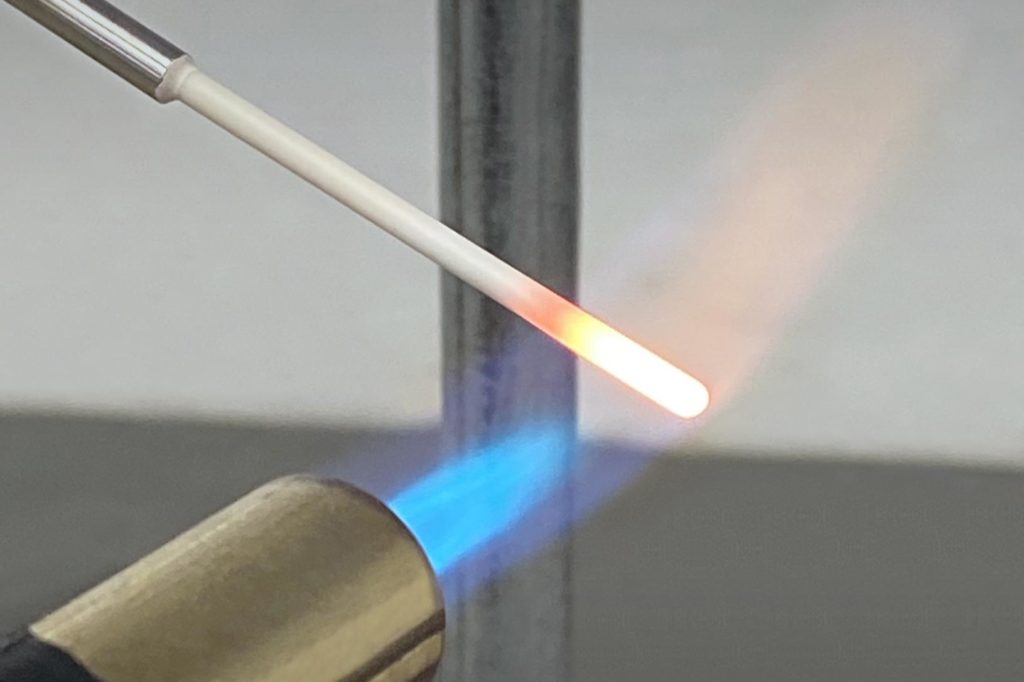

With its new platinum sensors, hotset is pushing forward into the upper performance ranges of contacting high-temperature measurement. This is because the precious metal sensors, which are offered in various configurations, are suitable for application temperatures of up to 1,600° C and meet high requirements for measurement accuracy. In medical and dental technology, they are already being used as part of innovative sintering and glazing processes.

Numerous processes in modern medical and dental technology are based on the use of high temperatures of 900° C and more. These include, for example, a range of sintering, glazing, melting and plasma technologies used for the manufacture and surface finishing of instruments and implants. Numerous high-temperature processes are also found in analytical and laboratory technology — for example, in autoclave and reactor systems for carrying out hydrogenations or catalyst tests. Designed for use in such demanding areas are the new HT1600‑P platinum probes from hotset, with which the well-known thermodynamics specialist is expanding the selection of temperature sensors in its hotcontrol product line. Device and equipment manufacturers in the medical, dental and laboratory technology sectors thus have a high-quality premium solution for the realization of innovative high-tech applications.

Precision solution for high-temp applications

As the naming suggests, the new precious metal sensor from hotset is suitable for measuring and monitoring temperatures of up to 1,600° C. It scores points across the entire temperature range. It scores over the entire measuring range with very high accuracies. “Even in the uppermost temperature zones, the HT1600‑P convinces with the smallest deviations of only +/- 1.0° C,” says hotset product manager Adrian Strojny. Due to this high accuracy, platinum probes are also used as references or standards in calibration technology. For manufacturers of medical and laboratory technology, this opens up new avenues for the development of high-temp solutions that require above-average temperature guidance and parameterization.

Much scope for special requests

Generally, hotset offers the new HT1600‑P platinum sensors in three basic configurations: As a temperature sensor in straight design according to DIN EN 50446, as a thermocouple with wire pair according to DIN EN 60584 as well as ANSI 96.1, and as a sheathed thermocouple according to DIN EN 61515 with thin-walled, flexible sheathed wires. “As usual with our thermocouples, however, we always tailor the construction and design of each HT1600‑P to the specific ideas and requirements of our customers,” emphasizes Product Manager Adrian Strojny. The possibilities of hotset reach here from the selection of many different connection contacts over the conversion of special desires regarding the shaping of the measuring sensor up to the adjustment to difficult installation situations or the calibration and stabilization of the thermocouple by purposeful tempering.

Optimal under protective gas

The optimal surrounding field for the new platinum sensors HT1600‑P of hotset form applications with protective gas atmosphere. However, they can also be used in normal air environments. Device and equipment manufacturers in medical and laboratory technology who need a high-precision sensor for the control, detection and monitoring of high-temperature processes, which can also convince with short response times and long-term stability, receive an extremely high-quality sensor solution with the HT1600‑P from hotset.

.