Company Profile

hotset UK

Hotset UK Ltd has been manufacturing heating elements since 1993. We are accredited to the recognised and respected BS EN ISO9001 : 2015 registered.

We manufacture and operate in the UK and are probably the UK’s No. 1 manufacturer and stockist of heating elements. We have a purpose built factory comprising of 10,000 sq ft and in addition to this we have further capacity of 6500 sq ft, allowing plenty of scope to expand our products and business within the UK and Worldwide.

Extensive manufacturing materials

Hotset UK hold extensive manufacturing materials which enable us to provide a fast and efficient service to our customers. We believe that with our dedicated workforce, nobody works harder than us in our industry, due to our manufacturing processes together with an advanced computer system to operate our CNC Trumpf Machines, Also to add to our production capabilities we have invested in new mica sheet and coil element winding machines, which gives us the capacity to enhance our service to all of our customers with Fast Turnaround, Quality and Price from order to despatch. We also offer an emergency breakdown servive to new and existing customers with no additional or hidden surcharges of the products we manufacture.

No order is too large or too small.

Why!! wait weeks for your heater bands when we can deliver the same day / next day.

Hotset UK Ltd believe that customer satisfaction is of vital importance in order to maintain long term relationships with our customers.

HOTSET UK LTD PROVIDE QUALITY AND SERVICE YOU CAN RELY ON

Manufacturing in the UK since 1993

Our Products

Hotset UK manufacture a wide range of Nozzle Heaters with various clamping methods and lead exits. All sizes below are rated 240 Volt, but other voltages are available.

| Size | Wattage | Size | Wattage | Size | Wattage | Size | Wattage |

|---|---|---|---|---|---|---|---|

| 25 x 25 | 100 | 32 x 25 | 115 | 38 x 25 | 140 | 45 x 25 | 175 |

| 25 x 30 | 100 | 32 x 30 | 140 | 38 x 30 | 160 | 45 x 30 | 185 |

| 25 x 32 | 120 | 32 x 32 | 150 | 38 x 32 | 170 | 45 x 32 | 200 |

| 25 x 35 | 130 | 32 x 35 | 160 | 38 x 35 | 190 | 45 x 35 | 225 |

| 25 x 38 | 140 | 32 x 38 | 175 | 38 x 38 | 200 | 45 x 38 | 240 |

| 25 x 40 | 150 | 32 x 40 | 180 | 38 x 40 | 225 | 45 x 40 | 250 |

| 25 x 45 | 165 | 32 x 45 | 200 | 38 x 45 | 275 | 45 x 45 | 275 |

| 25 x 50 | 180 | 32 x 50 | 230 | 38 x 50 | 275 | 45 x 50 | 325 |

| 30 x 25 | 100 | 35 x 25 | 140 | 40 x 25 | 140 | 50 x 25 | 180 |

| 30 x 30 | 130 | 35 x 30 | 150 | 40 x 30 | 175 | 50 x 30 | 220 |

| 30 x 32 | 140 | 35 x 32 | 160 | 40 x 32 | 180 | 50 x 32 | 235 |

| 30 x 35 | 150 | 35 x 35 | 175 | 40 x 35 | 150 | 50 x35 | 250 |

| 30 x 38 | 160 | 35 x 38 | 190 | 40 x 38 | 220 | 50 x 38 | 280 |

| 30 x 40 | 175 | 35 x 40 | 200 | 40 x 40 | 230 | 50 x 40 | 300 |

| 30 x 45 | 200 | 35 x 45 | 225 | 40 x 45 | 250 | 50 x 45 | 325 |

| 30 x 50 | 220 | 35 x 50 | 250 | 40 x 50 | 280 | 50 x 50 | 375 |

Available Styles

HS‑1 Leads out of thickness. For use in restricted areas with low profile lead exit, sizes range from 25mm diameter to 50 diameter fitted with or without steel over braid. When ordering state diameter, width, watts, volts, and lead length. The sizes listed above are available from stock at special prices for HS‑1 exit but larger sizes are available.

HS‑2 Leads out of width. Used in most applications with flexible leads exiting from either side of the clamp gap. When ordering state diameter, width, watts, volts, and lead length.

HS‑3 Leads axial exit out of nozzle box. For use only where there is sufficient clearance around the nozzle to allow for the terminal housing. when ordering state diameter, width, watts, volts and lead length.

HS‑4 Press Fit. Used where space is restricted to a minimum and there is insufficient room for a clamping arrangement. When ordering state diameter, width, watts, volts, and lead length.

Brass Sealed Nozzle / Standard HS1 Nozzle / Stainless Sealed Nozzle

Applications

Technical Data

| Outer material | Stainless Steel or Aludip |

| Insulation material | High temperature phlogopite mica |

| Standard thickness | 4mm approx |

| Winding material | High quality 80/20 NiCr |

| Voltage supply | up to 480 volts |

| Watt density | 3.5 watts cm2 |

| Maximum temperature | up to 300 °C |

| Resistance tolerance | +10% – 5% |

| Wattage tolerance | +5% – 10% |

Available Terminations

Hotset UK can manufacture Mica Band Heaters with a wide variety of termination options depending on the type of application and customer requirement. Options as listed below.

- 2 Pin Socket

- 3 Pin Euro Socket

- Post Terminals

- Ceramic Terminal Block

- Flying Leads

- Braided Leads

- Conduit

- Silicone Leads

- Strain Relief Clips or Grip Glands

Hotset UK manufacture Mica Plate Heaters to customer specification with a variety of termination options and shapes. Plates can also be manufactured as Discs, Box Shapes, L Shapes and U Shapes and can also be supplied with 3 and 6mm thick Clamping Plates.

Applications

Technical Data

| Outer material | Stainless Steel or Aludip |

| Insulation material | High temperature phlogopite mica |

| Standard thickness | 4mm approx |

| Winding material | High quality 80/20 NiCr |

| Voltage supply | up to 480 volts |

| Watt density | 3.5 watts cm2 |

| Maximum temperature | up to 300 °C |

| Resistance tolerance | +10% – 5% |

| Wattage tolerance | +5% – 10% |

Available Terminations

Hotset UK can manufacture Mica Plate Heaters with a wide variety of termination options depending on the type of application and customer requirement. Options as listed below.

- 2 Pin Socket

- 3 Pin Euro Socket

- Post Terminals

- Ceramic Junction Block

- Flying Leads

- Braided Leads

- Conduit

- Silicone Leads

- Strain Relief Clips or Grip Glands

Applications

Technical Data

| Outer material | Stainless Steel or Aludip |

| Insulation material | Ceramic steatite grade 211 |

| Standard thickness | 11mm approx |

| Winding material | High quality 80/20 NiCr wire |

| Voltage supply | up to 480 volts |

| Watt density | 7 watts cm2 |

| Maximum temperature | up to 450 °C |

| Resistance tolerance | +10% – 5% |

| Wattage tolerance | +5% – 10% |

Available Terminations

Hotset UK can manufacture Ceramic Band Heaters with a wide variety of termination options depending on the type of application and customer requirement. Options as listed below.

- 2 Pin Socket

- 3 Pin Euro Socket

- Post Terminals

- Ceramic Terminal Block

- Flying Leads

- Braided Leads

- Conduit

- Silicone Leads

- Strain Relief Clips or Grip Glands

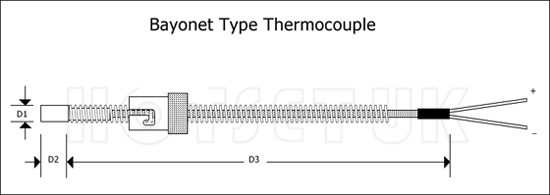

Stock Thermocouples

| Standard 8mm Dia x 10mm long tip with 14.5 ID bayonet cap, | |

| Sensor Type: „J“ | Grounded |

| Available Lengths | 2 and 3 Meters |

| Standard 6mm Dia x 15mm long tip with 12.5 ID bayonet cap, | |

| Sensor Type: „J“ | Grounded |

| Available Lengths | 2 Meters |

| Other configurations available on request | |

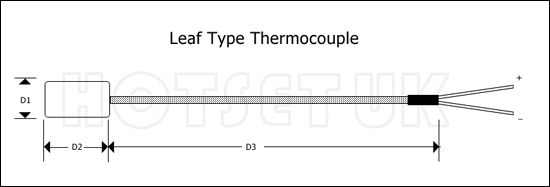

| Standard leaf type, | |

| Type „J“ | 1.0, 1.5, and 2.0 Meter lengths |

| Type „K“ | 1.0 Meter |

| Other configurations available on request | |

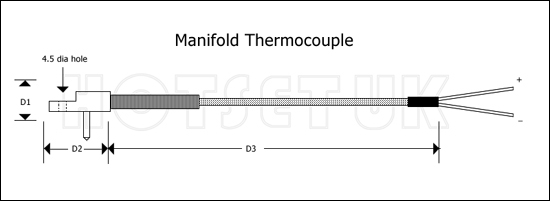

| Manifold thermocouple | |

| Sensor Type: „J“ | Grounded |

| Available Lengths | 2 and 3 Meters |

| Other configurations available on request | |

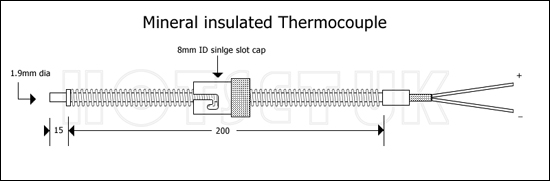

| 1.9 mm mineral insulated thermocouple | |

| Sensor Type: „J“ | Grounded |

| Available Lengths | 1.5 2,3 and 4 Meters |

| Other configurations available on request | |

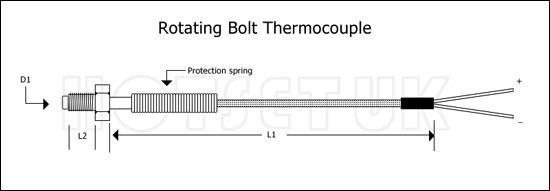

| Rotating Bolt Thermocouple | |

| Sensor Type „J“ | Grounded |

| Available lengths | 2 Meter |

| Bolt specification | M8 x 1.25 and M6 x 1.0 |

| Other configurations available on request | |

We also manufacture same day / next day

- PT100

- Melt Bolts

- Mineral Insulated

Thermocouple adaptors

| Thread | Pitch | Length | O/D | I/D | Type | No. Pins | Part No. |

| 1/8 | BSP | 25 | 11 | 6.5 | Barrel | 1 | 1/8BSPX25B |

| 1/8 | BSP | 30 | 11 | 6.5 | Barrel | 1 | 1/8BSPX30B |

| 1/8 | BSP | 35 | 11 | 6.5 | Barrel | 1 | 1/8BSPX35B |

| 1/8 | BSP | 55 | 11 | 6.5 | Barrel | 1 | 1/8BSPX55B |

| 1/8 | BSP | 65 | 11 | 6.5 | Barrel | 1 | 1/8BSPX65B |

| 1/4 | BSP | 50 | 14 | 8.5 | Barrel | 2 | 1/4BSPX50B |

| 1/4 | BSP | 75 | 14 | 8.5 | Barrel | 2 | 1/4BSPX75B |

| 3/8 | BSP | 50 | 14 | 8.5 | Barrel | 2 | 3/8BSPX50B |

| 3/8 | BSP | 50 | 14 | 8.5 | Hex | 2 | 3/8BSPX50H |

| M12 | 1.5 | 30 | 12 | 8.5 | Hex | 2 | M12X1.5X30X12H |

| M12 | 1.5 | 30 | 14 | 8.5 | Hex | 2 | M12X1.5X30X14H |

| M12 | 1.75 | 25 | 12 | 8.5 | Barrel | 2 | M12X1.75X25X12B |

| M12 | 1.75 | 30 | 12 | 8.5 | Hex | 2 | M12X1.75X30X12B |

| M12 | 1.75 | 32 | 14 | 8.5 | Hex | 2 | M12X1.75X32X14H |

| M12 | 1.75 | 50 | 14 | 8.5 | Barrel | 2 | M12X1.75X50X14B |

| M12 | 1.0 | 30 | 12 | 8.5 | Hex | 2 | M12X1X30X12H |

| M12 | 1.0 | 30 | 14 | 8.5 | Hex | 2 | M12X1X30X14H |

| M12 | 1.0 | 32 | 14 | 8.5 | Barrel | 2 | M12X1X32X14B |

| M12 | 1.0 | 32 | 14 | 8.5 | Hex | 2 | M12X1X32X14H |

| M12 | 1.0 | 50 | 14 | 8.5 | Barrel | 2 | M12X1X50X14B |

| M12 | 1.0 | 60 | 14 | 8.5 | Barrel | 2 | M12X1X60X14B |

| M12 | 1.0 | 70 | 14 | 8.5 | Barrel | 2 | M12X1X70X14B |

| M14 | 1.5 | 100 | 14 | 8.5 | Barrel | 2 | M14X1.5X100X14B |

| M14 | 1.5 | 20 | 14 | 8.5 | Barrel | 2 | M14X1.5X20X14B |

| M14 | 1.5 | 32 | 14 | 8.5 | Barrel | 2 | M14X1.5X32X14B |

| M14 | 1.5 | 50 | 14 | 8.5 | Barrel | 2 | M14X1.5X50X14B |

| M14 | 1.5 | 60 | 14 | 8.5 | Barrel | 2 | M14X1.5X60X14B |

| M14 | 1.5 | 70 | 12 | 8.5 | Barrel | 2 | M14X1.5X70X12B |

| M14 | 1.0 | 50 | 14 | 8.5 | Barrel | 2 | M14X1X50X14B |

| This list is not exhaustive and specials can be manufactured to customers specifications | |||||||

Applications

| Wattage | Width | ||||||||||

| MMØ | INCH | 20 | 40 | 60 | 80 | 100 | 120 | 140 | 160 | 180 | 200 |

| 10.0 | 195 | 240 | 350 | 350 | 350 | 400 | 460 | 460 | 610 | ||

| 12.0 | 215 | 295 | 400 | 400 | 400 | 460 | 610 | 610 | 610 | ||

| 12.5 | 1/2″ | 215 | 295 | 400 | 400 | 400 | 460 | 610 | 610 | 690 | |

| 14.0 | 240 | 350 | 400 | 400 | 460 | 610 | 610 | 690 | 690 | ||

| 15.0 | 240 | 400 | 460 | 460 | 610 | 610 | 610 | 690 | |||

| 16.0 | 5/8″ | 240 | 400 | 460 | 460 | 610 | 610 | 690 | 690 | ||

| 18.0 | 295 | 400 | 610 | 610 | 610 | 690 | 690 | ||||

| 19.0 | 3/4″ | 295 | 400 | 610 | 610 | 610 | 690 | ||||

| 20.0 | 295 | 460 | 610 | 610 | 690 | 690 | |||||

| 22.0 | 7/8″ | 195 | 350 | 610 | 690 | 690 | 690 | ||||

| 24.0 | 195 | 400 | 610 | 690 | 690 | ||||||

| 25.0 | 1″ | 215 | 400 | 610 | 690 | 690 | |||||

| 28.0 | 215 | 460 | 690 | ||||||||

| 30.0 | 240 | 460 | 690 | ||||||||

| 32.0 | 1 1/4″ | 240 | 460 | 690 | |||||||

| 35.0 | 295 | 610 | |||||||||

| 38.0 | 1 1/2″ | 295 | 610 | ||||||||

| 40.0 | 295 | 610 | |||||||||

| 42.0 | 350 | 610 | |||||||||

| 45.0 | 350 | 690 | |||||||||

| 48.0 | 400 | 690 | |||||||||

| 50.0 | 2″ | 400 | 690 | ||||||||

ther sizes are available on request. When ordering, specify inside Diameter and length. Various exits available as below.

Also various wattages available from stock 3.3 Round Section.

Applications

Immersion Heaters are designed and built for ease of installation, safety, reliability and easy maintenance even in difficult conditions.

Standard thread sizes BSP 1 1/4″, 1 3/4″, 2″, 2 1/4″ and 2 1/2″ but various alternatives are available on request.

We manufacture Cartridge Heaters Standard and Non Standard sizes 10 – 14 Days. We also offer an Express service which we will manufatutre within 5 Days.

Applications

| Diameter | Length | Watts | Volts | Notes |

| 6.3 | 38.1 | 200 | 230 | |

| 6.3 | 50.8 | 125 | 230 | |

| 6.3 | 63.5 | 125 | 230 | |

| 6.3 | 63.5 | 250 | 230 | |

| 6.3 | 63.5 | 250 | 230 | With J type T/C |

| 6.3 | 76.2 | 300 | 230 | |

| 6.3 | 76.2 | 315 | 230 | |

| 6.3 | 82.5 | 125 | 230 | |

| 6.3 | 82.5 | 350 | 230 | |

| 6.3 | 101.6 | 160 | 230 | |

| 6.3 | 101.6 | 220 | 230 | |

| 6.5 | 40 | 100 | 230 | With J Type T/C |

| 6.5 | 60 | 125 | 230 | |

| 6.5 | 60 | 160 | 230 | |

| 6.5 | 80 | 180 | 230 | |

| 6.5 | 80 | 250 | 230 | |

| 6.5 | 80 | 315 | 230 | |

| 6.5 | 100 | 160 | 230 | |

| 6.5 | 100 | 250 | 230 | |

| 6.5 | 100 | 350 | 230 | |

| 6.5 | 100 | 350 | 230 | With J Type T/C |

| 6.5 | 130 | 220 | 230 | |

| 6.5 | 130 | 350 | 230 | |

| 8.0 | 40 | 100 | 230 | |

| 8.0 | 40 | 250 | 230 | |

| 8.0 | 50 | 250 | 230 | |

| 8.0 | 80 | 315 | 230 | |

| 8.0 | 100 | 200 | 230 | |

| 8.0 | 100 | 315 | 230 | |

| 8.0 | 130 | 250 | 230 | |

| 8.0 | 160 | 200 | 230 | |

| 9.46 | 63.5 | 315 | 230 | |

| 9.46 | 63.5 | 400 | 230 | |

| 9.46 | 63.5 | 500 | 230 | |

| 9.46 | 76.2 | 250 | 230 | |

| 9.46 | 76.2 | 250 | 230 | With J Type T/C |

| 9.46 | 76.2 | 400 | 230 | |

| 9.46 | 76.2 | 400 | 230 | With J Type T/C |

| 9.46 | 76.2 | 500 | 230 | |

| 9.46 | 76.2 | 600 | 230 | |

| 9.46 | 82.5 | 400 | 230 | |

| 9.46 | 127 | 300 | 230 | |

| 9.46 | 133.3 | 400 | 230 | |

| 9.46 | 133.3 | 500 | 230 | |

| 9.46 | 152.4 | 750 | 230 | |

| 9.46 | 165.5 | 400 | 230 | |

| 10.0 | 40 | 125 | 230 | |

| 10.0 | 40 | 200 | 230 | |

| 10.0 | 50 | 250 | 230 | With J Type T/C |

| 10.0 | 60 | 125 | 230 | |

| 10.0 | 80 | 250 | 230 | |

| 10.0 | 80 | 315 | 230 | |

| 10.0 | 80 | 630 | 230 | |

| 10.0 | 100 | 250 | 230 | |

| 10.0 | 100 | 315 | 230 | |

| 10.0 | 100 | 350 | 230 | |

| 10.0 | 100 | 630 | 230 | |

| 10.0 | 100 | 850 | 230 | |

| 10.0 | 130 | 630 | 230 | |

| 10.0 | 130 | 800 | 230 | |

| 10.0 | 160 | 400 | 230 | |

| 12.5 | 50 | 100 | 230 | |

| 12.5 | 50 | 200 | 230 | |

| 12.5 | 60 | 200 | 230 | |

| 12.5 | 60 | 315 | 230 | |

| 12.5 | 60 | 400 | 230 | |

| 12.5 | 80 | 250 | 230 | |

| 12.5 | 130 | 630 | 230 | |

| 12.5 | 180 | 670 | 230 | |

| 12.61 | 38.1 | 160 | 230 | |

| 12.61 | 50.8 | 500 | 230 | |

| 12.61 | 57.2 | 300 | 230 | |

| 12.61 | 63.5 | 315 | 230 | |

| 12.61 | 63.5 | 500 | 230 | |

| 12.61 | 76.2 | 300 | 230 | |

| 12.61 | 76.2 | 600 | 230 | |

| 12.61 | 82.5 | 200 | 230 | |

| 12.61 | 82.5 | 315 | 230 | |

| 12.61 | 82.5 | 500 | 230 | |

| 12.61 | 82.5 | 630 | 230 | |

| 12.61 | 82.5 | 800 | 230 | |

| 12.61 | 101.6 | 250 | 230 | |

| 12.61 | 101.6 | 400 | 230 | |

| 12.61 | 101.6 | 500 | 230 | |

| 12.61 | 101.6 | 800 | 230 | |

| 12.61 | 127 | 750 | 230 | |

| 12.61 | 152.4 | 500 | 230 | |

| 12.61 | 152.4 | 750 | 230 | |

| 12.61 | 165.1 | 800 | 230 | |

| 12.61 | 165.1 | 1200 | 230 | |

| 15.81 | 38.1 | 230 | 230 | |

| 15.81 | 38.1 | 315 | 230 | |

| 15.81 | 50.8 | 160 | 230 | |

| 15.81 | 50.8 | 400 | 230 | |

| 15.81 | 50.8 | 500 | 230 | |

| 15.81 | 63.5 | 250 | 230 | |

| 15.81 | 76.2 | 750 | 230 | |

| 15.81 | 76.2 | 1000 | 230 | |

| 15.81 | 82.5 | 400 | 230 | |

| 15.81 | 82.5 | 630 | 230 | |

| 15.81 | 127 | 750 | 230 | |

| 15.81 | 127 | 1000 | 230 | |

| 15.81 | 133.3 | 500 | 230 | |

| 15.81 | 133.3 | 1100 | 230 | |

| 15.81 | 203.3 | 1500 | 230 | |

| 15.81 | 304.4 | 1800 | 230 | |

| 16.0 | 40 | 250 | 230 | |

| 16.0 | 50 | 250 | 230 | |

| 16.0 | 50 | 400 | 230 | |

| 16.0 | 60 | 315 | 230 | |

| 16.0 | 60 | 630 | 230 | |

| 16.0 | 80 | 500 | 230 | |

| 16.0 | 80 | 630 | 230 | |

| 16.0 | 80 | 800 | 230 | |

| 16.0 | 130 | 1000 | 230 | |

| 16.0 | 160 | 630 | 230 | |

| 16.0 | 160 | 800 | 230 | |

| 16.0 | 250 | 1000 | 230 | |

| 16.0 | 250 | 1250 | 230 | |

| 16.0 | 250 | 1600 | 230 | |

| 20.0 | 60 | 800 | 230 | |

| 20.0 | 80 | 350 | 230 | |

| 20.0 | 80 | 800 | 230 | |

| 20.0 | 80 | 1000 | 230 | |

| 20.0 | 100 | 1000 | 230 | |

| 20.0 | 100 | 1600 | 230 | |

| 20.0 | 130 | 630 | 230 | |

| 20.0 | 130 | 900 | 230 | |

| 20.0 | 130 | 1250 | 230 | |

| 20.0 | 160 | 800 | 230 | |

| 20.0 | 300 | 1600 | 230 |

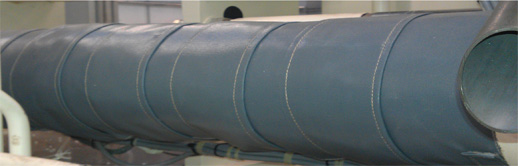

Hotset UK Insulation Jackets can be used in conjunction with your existing heater bands without the need to replace them, they can also be manufactured as a complete unit with heaters built in.

Our Insulation Jackets consist of high temperature, high tensile graphite coated silica hot face and designed to operate at 1200 ° C. The Insulation Jackets benefit from a rigid Teflon outer face that can be easily wiped clean

Hotset UK Insulation Jackets can be used in conjunction with your existing heater bands without the need to replace them, they can also be manufactured as a complete unit with heaters built in.

Our Insulation Jackets consist of high temperature, high tensile graphite coated silica hot face and designed to operate at 1200 ° C. The Insulation Jackets benefit from a rigid Teflon outer face that can be easily wiped clean

The inner blanket is made from high density wool with superior insulating properties that will not breakdown under extreme temperatures. The Jackets are fastened using high temperature stainless hook and loop velcro.

We manufacture Insulation Jackets with cutouts to accommodate terminal boxes, thermocouple holes and stanchion supports and are available in various thickness, to accommodate restricted access from guards.

If you would like advice on how to prepare a survey for Insulation, please do not hesitate to contact us.

Benefits Include

- Faster start up times

- Increased Cycle times

- Minimum 30% energy savings

- Cold surface reduces risk of burns

- Environmentally friendly

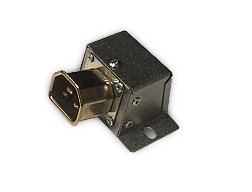

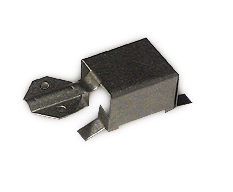

| Description | Part Number | Image | Rating |

| 3‑Pin Rubber Silicone Straight | 3‑PRSS |  | 16 Amps 250V~ 200° C |

| 3‑Pin Rubber Silicone 90 Degree Angled | 3‑PRSA |  | 16 Amps 250V~ 200° C |

| 2‑Pin Rubber Silicone Straight | 2‑PRSS |  | 16 Amps 250V~ 200° C |

| 2‑Pin Rubber Silicone 90 Degree Angled | 2‑PRSA |  | 16 Amps 250V~ 200° C |

| 2‑Pin Ceramic Ali Straight | 2‑PCAS |  | 24 Amps 380V~ 200° C |

| 2‑Pin Ceramic Ali 90 Degree Angled | 2‑PCAA |  | 24 Amps 380V~ 200° C |

| 3‑Pin Socket | 3‑PS |  | 16 Amp 250V~ |

| 2‑Pin Ceramic Socket | 2‑PCS |  | 10 Amp 250V~ |

| 3‑Pin Bayonet | 3‑PB-TCP |  | 10 Amp 250V~ |

| 3‑Pin Bayonet Socket | 3‑PB-TCS |  | 10 Amp 250V~ |

| 3‑Pin Screw Plug | 3‑PS-TCP |  | 10 Amp 250V~ |

| 3‑Pin Screw Socket | 3‑PS-TCS |  | 10 Amp 250V~ |

Our own brand of Hotset UK Mould Shop Sprays consists of, Mould Cleaner Degreaser, Silicone Mould Release, Non-Silicone Mould Release, Green Moisture Guard, Clear Moisture Guard, and HS-40 Maintenance Spray. Data sheets available on request.

|  |  |  | ||||||||||||||||||||||||||||||||||

|

|

|

| ||||||||||||||||||||||||||||||||||

|  |  |  | ||||||||||||||||||||||||||||||||||

|

|

|

| ||||||||||||||||||||||||||||||||||

|  |  |  | ||||||||||||||||||||||||||||||||||

|

|

|

| ||||||||||||||||||||||||||||||||||

|  |  |  | ||||||||||||||||||||||||||||||||||

|

|

|

|

Contact

Hotset UK Limited

Unit 1, West Road,

Penallta Industrial Estate,

Penallta,

Hengoed

CF82 7QZ

Tel:- 01443 813500 | Fax:- 01443 819536 | Email:- sales-uk@hotset.com