System Center for Industrial Temperature Control (SIT)

System Center

Here you will have the opportunity to get to know — and extensively test — our latest innovations in the field of targeted temperature control of molds and process media as well as semi-finished products and products made of plastics. In a professional atmosphere, in professional discourse with hotset’s thermodynamics specialists and in the environment of a technologically modern equipped pilot plant.

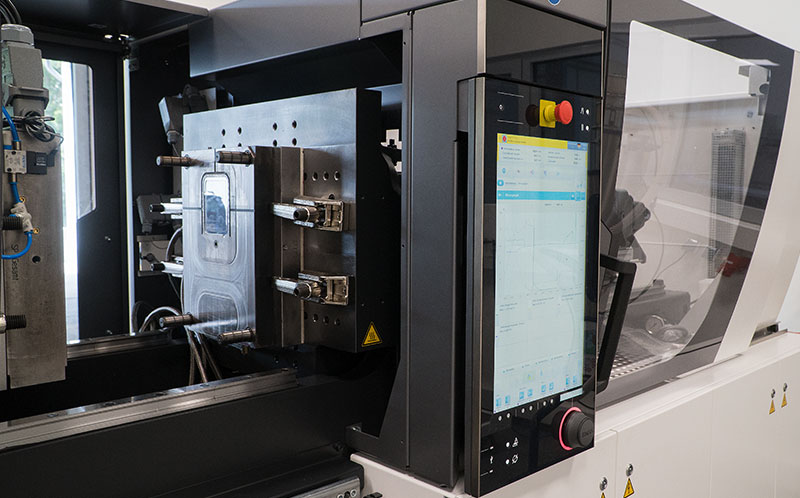

The start-up is a facility of the thermodynamics specialist hotset and offers professionals from plastics technology and toolmaking the opportunity to learn first-hand in full detail about the performance of the DH-System. The high-speed process for partial-cycle cavity temperature control is considered by experts to be one of the most important innovations in the field of variothermal mold temperature control. It will be presented in an ENGEL injection moulding machine in the new System Center. The Austrian machine manufacturer and system expert supports hotset’s temperature control process with innovative injection molding technology.

ThinkTank for injection molders, mold makers and product developers

You want to improve the quality of your plastic products and are on the lookout for forward-looking developments in the field of temperature control technology?

You are looking for new perspectives for optimizing the surface design of molded parts and films made of plastic or for realizing polymer microstructures?

You are asking about processes and systems with which temperatures can be accurately controlled to the target at the right moment?

Then we would like to welcome you to the System Center for Industrial Temperature Control Technology (SIT) in Lüdenscheid! Here you will have the opportunity to get to know — and extensively test — our latest innovations in the field of targeted temperature control of molds and process media as well as semi-finished products and products made of plastics. In a professional atmosphere, in professional discourse with the thermodynamics specialists from hotset and in the environment of a technologically modern equipped pilot plant.

Current focus: The DH-System

Currently, the SIT topic focus is on the practical presentation and demonstration of the DH-system for partial-cyclic temperature control of the cavities of injection molds. For this purpose, we have installed a complete injection moulding workflow in the SIT premises: With SGM from ENGEL, the control technology for the DH-system as well as mold fixtures, cooling water treatment and material drying system.

As a plastics processor, mold maker and product developer, this workflow will be freely available to you over the next few weeks. Focused on your individual task, you can — accompanied by SIT’s team of experts — run through the use of the DH-System under production conditions. In addition, you will have the opportunity to run concrete samples or material tests — with all variants of the DH-System: the fully integrated machine solution, the stand-alone version or the retrofit set.

Take advantage of this opportunity to find out individually and at first hand about what is currently probably the most innovative temperature control process in the field of plastics injection molding technology.