Even surface temperature control in foil technology

P‑System heating plates

With the surface heating plates of our P‑System, we offer you an innovative system solution for the process-reliable generation of uniform and homogeneous surface temperature control during the processing of a wide variety of materials. Particularly in film technology, the use of our heating plates offers numerous advantages over standard solutions for surface temperature control.

Heating plates in foil technology

The aspect of precise surface temperature control plays a central role in many film technology processes. Generating uniform and homogeneous temperature fields over large areas is particularly demanding in terms of process technology. This is important, for example, in the thermoforming of food packaging, in the processing of shrink and stretch films, or in film welding. Our heating plate offers an ideal solution for this task.

P‑System heating plates for optimum surface temperature control

Do you want to create convergent and homogeneous surface temperature control over large areas of plastic films in film technology — for example, when thermoforming or thermoforming blister packs and plastic trays?

For plastics, are you looking for a way to achieve uniform surface temperature control of packaging films, such as tubular , shrink or stretch films?

Do you need a process-reliable and precisely controllable surface temperature control system for film sealing, hot pressing, sealing or vacuuming?

The solution for all these tasks is our versatile heating plate for surface heating of plastic films and many other materials!

- Highly accurate: Gradual temperature deviations of only 2 °C ensure homogeneous temperature distribution over the entire area covered by the heating plate and thus optimum surface temperature control

- Complete solution: Ready-to-mount heating plate including connection and fastening technology for easy integration into machines, systems and equipment for thermoforming, deep drawing, film welding, hot pressing, etc.

- Individual: Customer- and project-specific dimensioning, design, coating and configuration of all system components

- Flexible: supply voltages from 12 to 400 volts and power densities of up to 15 W/cm²

Higher process reliability for film technology

With the surface heating panels of our P‑System, we offer you an innovative system solution for the process-safe generation of a uniform and homogeneous surface temperature control during the processing of, among other things, plastics used in thermoforming, thermoforming, film welding, hot pressing, etc.

The decisive factor here is that the temperature values of the film heated with a P‑System surface heating plate from hotset varied only minimally throughout the entire temperature control field; maximum deviations of no more than 2 °C are characteristic. This gives you an extremely precise and process-reliable system that supports the production of high-quality film products for packaging technology.

P‑System surface heating plates from hotset are always ready-to-install complete solutions whose design and thermodynamic configuration are optimally adapted to the individual requirements of machine and plant manufacturers in the various areas of film technology. Whether for thermoforming blister packs or plastic pallets, for film sealing tubular bags or many other tasks — the heating plate system can be precisely adapted to any surface temperature control situation.

The most important questions for the design of a heating plate

The following 6 questions are relevant:

- What is heated in the process?

- What temperature should be supplied?

- What kind of temperature fluctuations are tolerable?

- In what kind of time period should the heating take place?

- What specific location is to be heated?

- What are the ambient conditions?

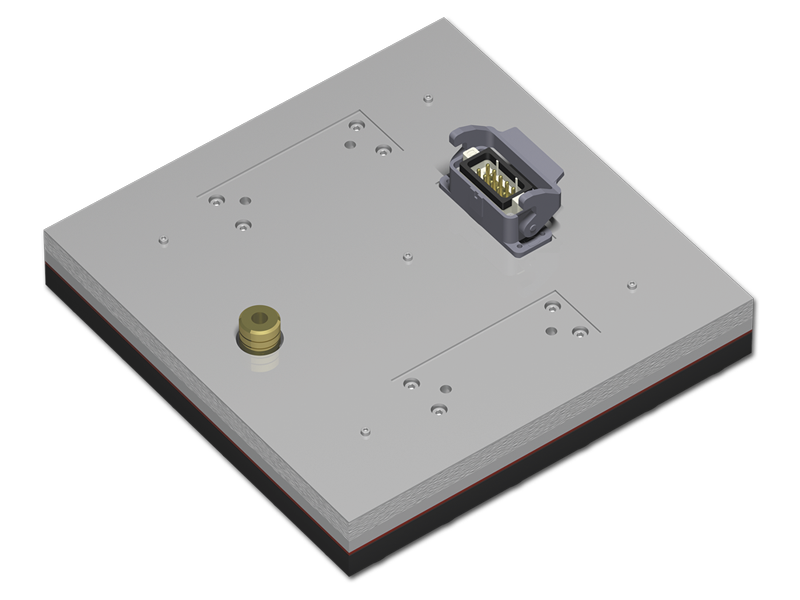

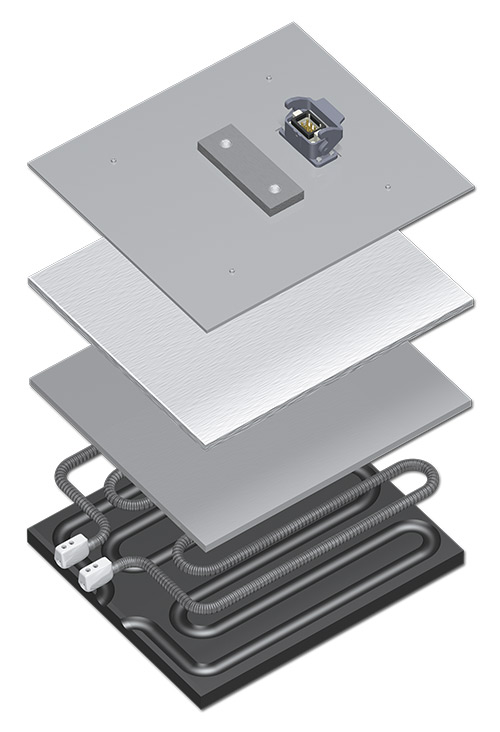

Structure of a heating plate for the foil technique

Structure details

- From the heat transfer plate. Depending on the application, this can be additionally provided with a functional coating. The additional coating can have different properties, such as wear protection or non-stick properties.

- The integrated heating element with optional temperature sensors. Here, depending on the requirements, different heating elements can be selected:

- The insulating/insulating plate An intermediate plate or cover plate for installation and mounting

- Miscellaneous, such as the connecting cable and plug connection

Foil technology: Thinner, lighter, more accurate

The homogeneous surface temperature control of the P‑System panel heating plate produces very uniform film wall thicknesses, which reduces weight differences on the end product to a minimum. In addition, thinner films can be used — for example in thermoforming — which conserves resources, and unwelcome streaks in the packaging material can also be avoided. Another plus point when processing in film technology: damage to sensitive functional layers can be avoided with the use of an appropriate P‑System heating plate.

The advantages of P‑System surface heating plates in terms of the quality of the end products can also be quantified in concrete figures. Practical series of measurements all led to the result that the temperature values of the film heated with such a surface heating plate from hotset fluctuate only minimally in the entire tempering field. Characteristic are punctual deviations on the foil of at most 2 °C! In contrast, the surface temperature differences of conventional standard heating panels reach up to 15 °C. For all those equipment and plant manufacturers for whom precise and homogeneous surface temperature control represents a decisive process stage in their technical processes (e.g. thermoforming, deep drawing, film welding and hot pressing), this heating plate is virtually an ideal solution.

Surface temperature control individualized at all levels

The possibilities for customer and project-specific customization of our P System surface heating panels extend across all components and levels. The design of the heat transfer plate, the selection of the heating element (hotflex flexible tubular heater, hotform silicone heating element, etc.), the material of the insulating plate or the question of whether an installation space intermediate plate is required — everything is designed for your specific application from the foil technology or other areas. This also applies to the design of the cover plate with the plug-in contacts and fastening elements for installation in your thermoforming line, your blister or vacuum machine, your film sealing device, and, and, and.

Even when it comes to designing the surfaces of the heat transfer plate, we offer you a wide range of options: Functional coatings with antistatic , non-stick and aseptic properties can be realized as well as surfaces with increased wear , abrasion and corrosion protection. The hot platen is designed completely according to your requirements for thermoforming, deep drawing, film welding, hot pressing, and so on.

What is clear to us is that thermoforming of plastics, such as for blister packs or plastic trays, places different demands on the thermodynamics of hot platens than does the welding of tubular bag films.

Furthermore, temperature sensors can also be integrated to protect against excess temperatures.

We are also able to take into account special requirements for sliding properties, surface hardness, chemical resistance, electrical conductivity and ease of cleaning. And if required, we can also structure and contour the surfaces of our P System surface heating panels.

Heating plates for thermoforming plastics

Details about hot plates for thermoforming

Our heating plates, which are designed for thermoforming, are installed in machines. They heat the rigid film drawn from large rolls to make it soft and formable. This process is also known as thermoforming. The uniformly heated film can now be pressed into any shape, so that after cooling, it retains this shape permanently. This production process is used to create packaging for cheese and sausage or blister packaging for electrical appliances.

Heating plates for film welding

Details about heating plates for film welding

Our heating plates, which are designed for film welding, are used in various devices. They heat the two foils that are being welded to the desired temperature. With a mechanical pressure the heated foils are pressed together. After cooling, they are permanently joined, providing a stable closure of bags as well as films.

Heating plates for hot pressing

Details about hot press heating plates

Our heating plates, which are designed for hot pressing, are installed in various equipment to ensure forming in the process with targeted surface temperature control.

Other areas of application for heating plates

Composite materials

Composites made of several materials that are pressed together by hot pressing and thus permanently bonded together

Automotive industry

In the automotive industry for thermoforming, bonding and hot pressing of textiles and molded parts in the exterior and interior of the vehicle

Adhesive technology

Adhesive technology for curing adhesive beads

Composite glass

Production of composite glass, such as for solar installations

Rubber goods industry

In the rubber goods industry for heating vulcanizing molds

Others

General heating of containers and processing tables