One idea ahead

hotspring Coil Heaters

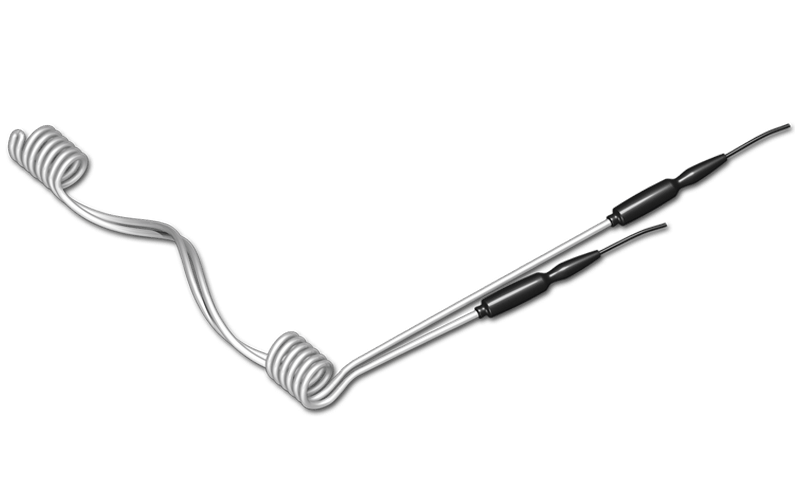

hotset was already in 1980 one idea ahead as they presented the first round hotspring coil heater. Since then further innovations have been made: hotspring®/Mini (type WRP 1,3 x 2,3), flat and square, hotspring®/Maxi (type WRP 4,8 x 8,6) as well as hotspring®/Micro (type WRP 1,3 x 2,3).

This innovation as well as the humidity-resistant coil heaters according to I.P. 65 (type WRP/F 2.2 x 4.2 — WRP/Q 3.0 x 3.0) emphasize the consequente alignment to new challenges.

Application examples

hotset offers a wide product range of hotspring coiled tubing cartridges: Starting from the hotspring Micro (type WRP/F 1.0 x 1.6) to the hotspring Maxi (type WRP 4.8 x 8.6) in a wide variety of lengths and diameters, hotspring with sleeve and clamping mechanism as heating elements for a wide variety of applications as well as a wide range of applications.

- Hot runner technology — heating of manifolds

- Packaging industry — heating of sealing bars

- Hot runner technology — heating of hot runner nozzles

- Packaging industry — heating of sealing heads

Stock Range

You can check our favorable stock assortment in our brochure in the download area. It is located on pages 4 — 7. Please inquire about our stock assortment via our standard inquiry form.

hotspring with reflection tube

When using hotspring coil heaters with a reflection tube the maximum surface load increases. Furthermore the reflection tube protects the heater from mechanical damages. The reflection tube can be delivered for a lot of hotspring dimensions. Additionally it is possible to carry out a controlled temperature measurement with a coiled-in or integrated thermocouple.

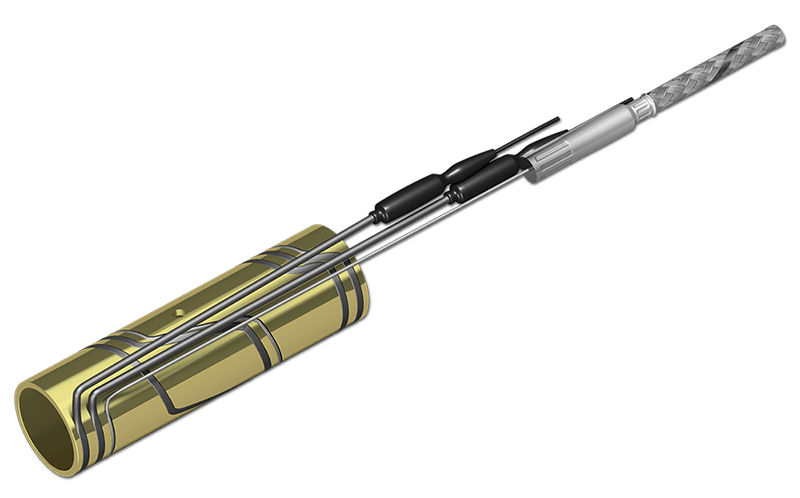

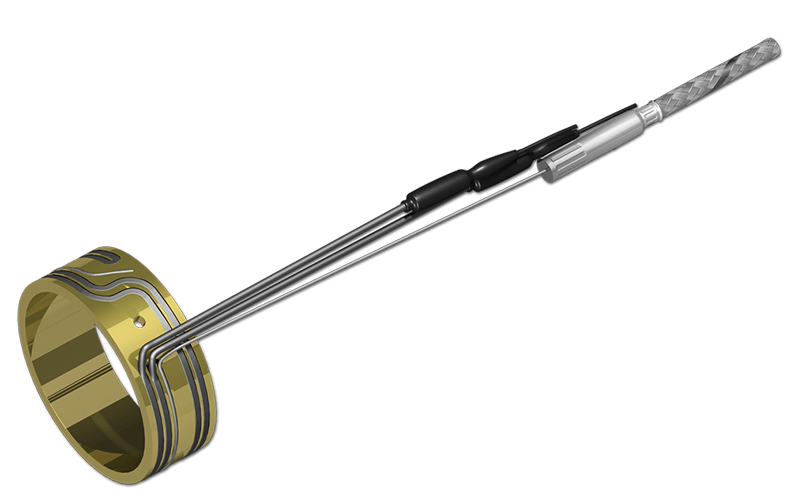

hotslot Nozzle Heating Elements

The hotslot is a heating element for heating hot runner nozzles for plastic injection molding. It is based on the proven technology of the “hotspring Mini” and “hotspring Micro” coiled tubing cartridges, which are pressed into a brass carrier tube.

Due to its low wall thickness, starting at 1.5 mm for the hotslot Micro, the hotslot allows minimum nest distances. In addition to the connection designs, analogous to the hotspring coiled tubing cartridge, the course of the groove for the heater to be pressed in can also be individually selected for the hotslot. The power distribution is thus absolutely precise and reproducible to ensure targeted and homogeneous temperature control in the manufacturing process.

The combination of brass carrier and helical cartridge allows for low-power zones that would be inconceivable with a simple helical cartridge. Even meander windings, recesses, apertures and bores as well as designs as a flat plate heating element are possible. To facilitate subsequent disassembly, the carrier tube can be nickel-plated.

Thermocouples are integrated with an additional slot and can also be placed individually. On request, hotset produces the hotslot with a slotted or partially slotted carrier tube with meander winding. This offers the advantage that the thermocouple can be changed easily if required. In addition to the customized options, hotset also offers several variants of the hotslot with thermocouple as standard items from stock.