Own development and production

hotcontrol Thermocouples and RTDs

hotcontrol Thermocouples and RTDs

In addition to a wide range of heating elements and control devices, hotset also offers thermocouples and resistance thermometers manufactured and developed in-house.

Application areas:

- Plastics industry

- Mechanical engineering

- Steel industry

- Chemical industry

- Ceramic and glass industry

- Energy industry

- Pharmaceutical industry

- Furnace industry

- Engine test benches

- Packaging industry

- Automotive industry

Thermocouples

A thermocouple consists of two wires of different material, which due to the thermoelectric effect generate a voltage from which the temperature can be derived.Depending on the desired application temperature, you can choose different thermocouples.

- Type J iron copper nickel according to DIN EN 60584 and ANSI 96.1

- Type L iron copper nickel according to DIN 43710

- Type K nickel chrome nickel according to DIN EN 60584 and ANSI 96. 1

- Type K nickel-chromium-nickel according to DIN 43710

- Types E, R, S and T according to DIN EN 60584 and ANSI 96. 1

- Type N according to DIN EN 60584

- Type B according to ANSI 96.1

- Type U according to DIN 43710

Properties and advantages:

- Also applicable in higher temperature ranges, such as. Types B, R and S which are temperature resistant up to 1600°C

- Short response time to temperature changes for fast reactions of the controlled system, especially with potential-containing measuring point

- Robust to mechanical stress and less sensitive than e.g. resistance thermometers to shocks and vibrations

- Very common and well-known sensor type

- Effectively priced

RTDs

In many areas of industry, temperature is measured with resistance thermometers. For this purpose, an ohmic resistor is used as the temperature sensor. Its resistance value is temperature-dependent. Platinum has become established as the resistor material. The most commonly used platinum alloy bears the designation Pt100, which we manufacture in accordance with DIN EN 60751.Other types of sensors available include. For example:

- Pt100

- Pt500

- Pt1000

- Ni100

- Ni120

- various NTC sensors

Properties and advantages:

- higher measuring accuracy than thermocouples

- best long-term stability

- high chemical resistance due to platinum

Designs of the temperature sensors

Sensors of all designs can basically be supplied as thermocouples and resistance thermometers.

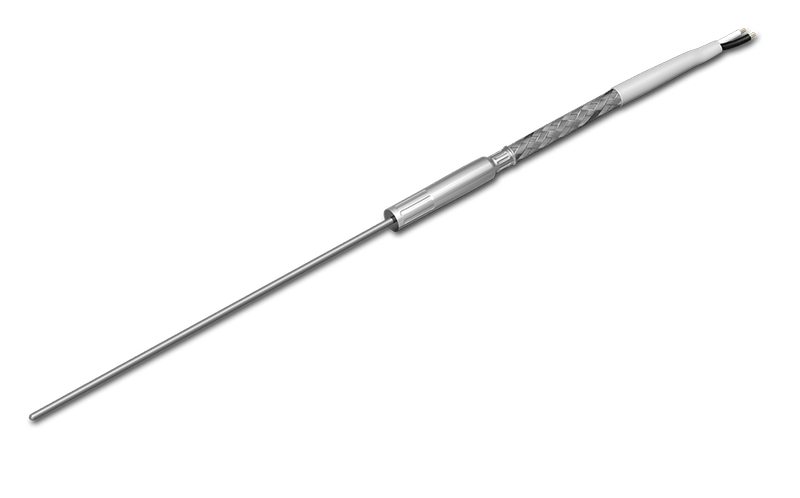

Mineral Insulated Thermocouples/RTDs

Mineral-insulated thermocouples / sheathed resistance thermometers, also known as mineral-insulated thermocouples / resistance thermometers, represent a special design of temperature sensors. They consist of a flexible thin-walled sheathed cable, which enables a long service life due to its vibration-resistant construction. They differ from other temperature sensors by their compact design, short response times to temperature changes and pliability, so that they can also be brought to measuring points that are difficult to access.

The sheath is easy to weld and solder due to the material (1.4541 and 2.4816), has the best strength properties at higher temperatures and meets the typical requirements in environments with gaseous and liquid media.

Connection plugs and compression fittings are available in numerous variations.

Connection types:

Mineral-insulated thermocouples / sheathed resistance thermometers, also known as mineral-insulated thermocouples / resistance thermometers, represent a special design of temperature sensors. They consist of a flexible thin-walled sheathed cable, which enables a long service life due to its vibration-resistant construction. They differ from other temperature sensors by their compact design, short response times to temperature changes and pliability, so that they can also be brought to measuring points that are difficult to access.

The sheath is easy to weld and solder due to the material (1.4541 and 2.4816), has the best strength properties at higher temperatures and meets the typical requirements in environments with gaseous and liquid media.

Connection plugs and compression fittings are available in numerous variations.

Connection types:

- Open ends

- Transition sleeves

- LEMO connectors

- Compensation connectors

- Mini compensation connectors

- Numerous other connection types on request.

- Hot runner nozzles

- Fume gas analysis

- Furnace construction/plants

- Steel works

- Laboratories

- Test facilities and test benches

Angle Thermocouples and RTDs (Types PWF 1 and TEF 12)

Suitable for temperature detection on injection and die casting molds in plastic and zinc die casting. Angle sensors are advantageous wherever no straight cable outlet is possible or desired, e.g. for reasons of space. The anti-kink spring of the connecting cable serves as mechanical protection. The fastening is carried out, for example, with a compression fitting or a screw-in thread.

Suitable for temperature detection on injection and die casting molds in plastic and zinc die casting. Angle sensors are advantageous wherever no straight cable outlet is possible or desired, e.g. for reasons of space. The anti-kink spring of the connecting cable serves as mechanical protection. The fastening is carried out, for example, with a compression fitting or a screw-in thread.Insert Surface Thermocouples and RTDs (Types TEF 2/PWF 2)

Plug-in sensors are preferably used for temperature measurements in solids, e.g. hot glue application heads or welding / sealing jaws of packaging machines.

The transition of the cable to the protective tube is strain-relieved. The stainless steel thermowell protects the measuring point against chemical influences and mechanical damage.

Fixing is by direct insertion into the borehole or by a flange.

Plug-in sensors are preferably used for temperature measurements in solids, e.g. hot glue application heads or welding / sealing jaws of packaging machines.

The transition of the cable to the protective tube is strain-relieved. The stainless steel thermowell protects the measuring point against chemical influences and mechanical damage.

Fixing is by direct insertion into the borehole or by a flange.Thermocouples and RTDs with Bayonet Cap (Types TEF or PWF 4, 11, 16, 20)

Thermocouples and resistance thermometers with bayonet lock are preferably used for temperature measurements in solids, sliding bearings and tools, e.g. in the plastics industry during plastic injection molding or extrusion.

Due to the special shape of the measuring tip, these temperature probes are suitable for use in flat and pointed bores.

The dimensionally stable pressure spring made of rust- and acid-resistant stainless steel, which also assumes the bend protection, ensures a constant contact pressure of the measuring tip in the borehole. The installation length can be varied by twisting the bayonet cap.

The diameter of the bayonet cap is available in several dimensions.

Screw-in adapters are available in various designs.

Thermocouples and resistance thermometers with bayonet lock are preferably used for temperature measurements in solids, sliding bearings and tools, e.g. in the plastics industry during plastic injection molding or extrusion.

Due to the special shape of the measuring tip, these temperature probes are suitable for use in flat and pointed bores.

The dimensionally stable pressure spring made of rust- and acid-resistant stainless steel, which also assumes the bend protection, ensures a constant contact pressure of the measuring tip in the borehole. The installation length can be varied by twisting the bayonet cap.

The diameter of the bayonet cap is available in several dimensions.

Screw-in adapters are available in various designs.Ring Thermocouples (Types TEF 13/30)

Ring thermocouples were developed for temperature measurement on surfaces. These are easy to attach with a screw and are suitable for numerous applications, e.g. hot runner manifolds.

Ring thermocouples were developed for temperature measurement on surfaces. These are easy to attach with a screw and are suitable for numerous applications, e.g. hot runner manifolds.Surface Thermocouple (Type TEF A)

For temperature measurement on pipelines and all cylindrical shapes. Attachment is by welding or soldering. The anti-kink spring of the connecting cable serves as mechanical protection.

For temperature measurement on pipelines and all cylindrical shapes. Attachment is by welding or soldering. The anti-kink spring of the connecting cable serves as mechanical protection.Clamping Band Thermocouple (Type TEF SP)

Common terms are also pipe clamp thermometers or pipe clamp resistance thermometers. They are used for temperature measurement on pipelines and cylindrical bodies. Fastening is done with the adjustable clamping band. The anti-kink spring of the connecting cable serves as mechanical protection.

Common terms are also pipe clamp thermometers or pipe clamp resistance thermometers. They are used for temperature measurement on pipelines and cylindrical bodies. Fastening is done with the adjustable clamping band. The anti-kink spring of the connecting cable serves as mechanical protection.Flange Mounted Thermocouple (Type TEF 68)

For temperature measurement on molds, e.g. hot runner manifolds.

This sensor is particularly space-saving and easy to attach to the flange with a screw. The anti-kink spring on the connecting cable serves as mechanical protection.

For temperature measurement on molds, e.g. hot runner manifolds.

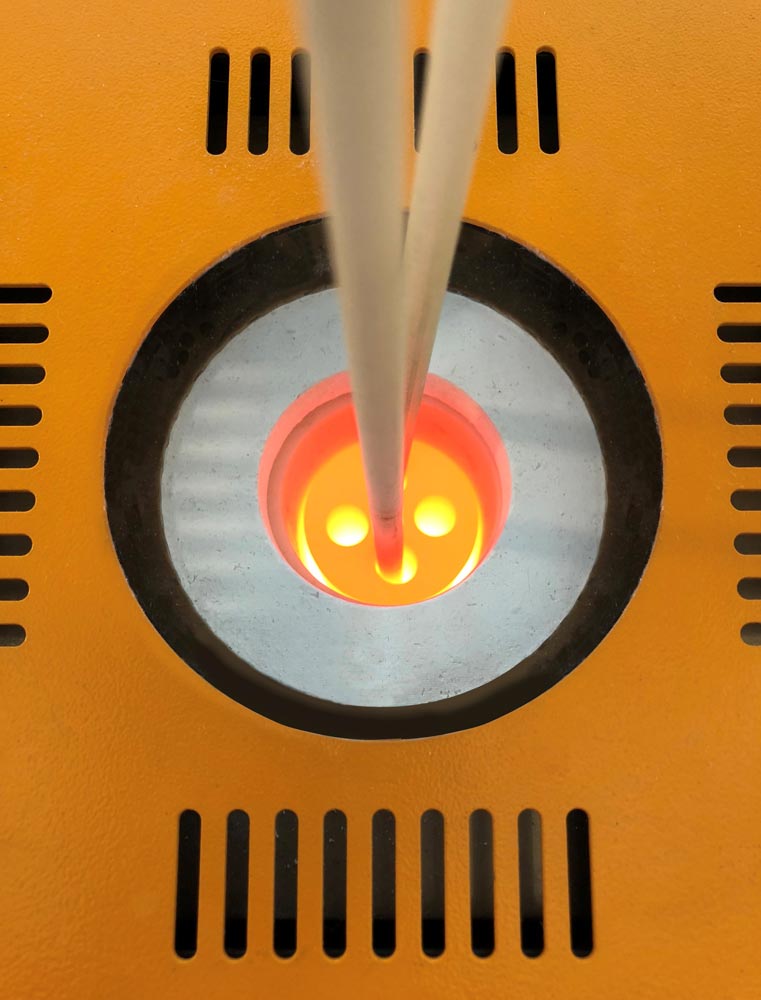

This sensor is particularly space-saving and easy to attach to the flange with a screw. The anti-kink spring on the connecting cable serves as mechanical protection.Calibration laboratory

In hotset’s in-house calibration laboratory, temperature sensors manufactured on customer request receive their metrological classification and a test certificate based on DIN EN ISO/IEC 17025.

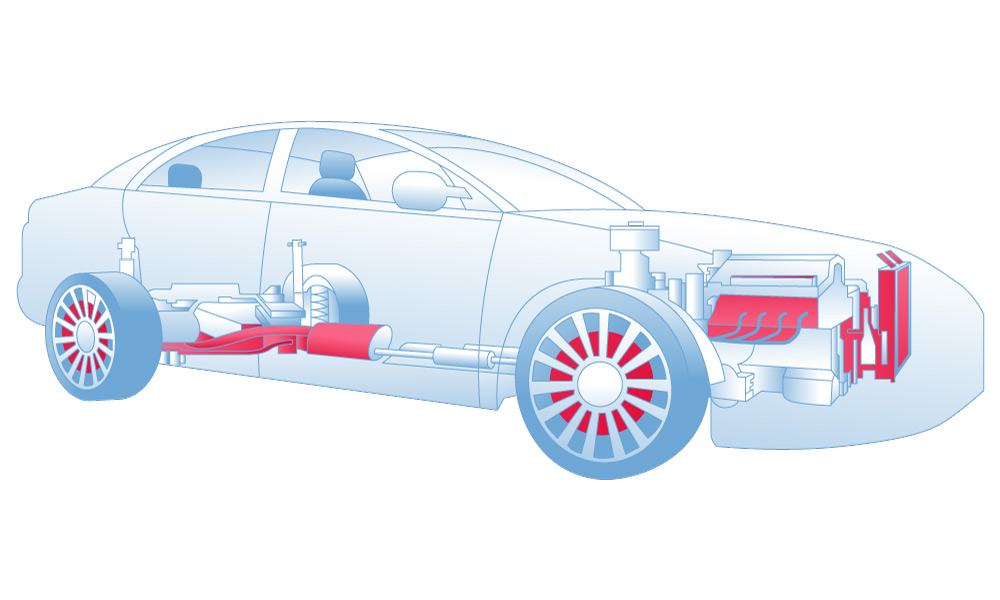

hotcontrol Automotive Sensors

Temperature sensors for research and development in the automotive industry.

Mineral Insulated Thermocouple / Mineral Insulated Resistance Thermometer

General application areas

General application areas - engine compartment

- Catalytic converter

- Exhaust tract

Wire thermocouple

Self-Adhesive surface thermocouple

Spring thermocouple / Friction thermocouple

Insert Thermocouple