Homogenous surface tempering

hotform Silicone Heating Elements

hotform silicone heating elements are the highly efficient, energy-saving and fast-reacting universal solution for homogeneous surface temperature control. Innovative heating conductor geometry and highly thermally conductive special silicone guarantee rapid heat transfer and exceptionally even heat distribution.

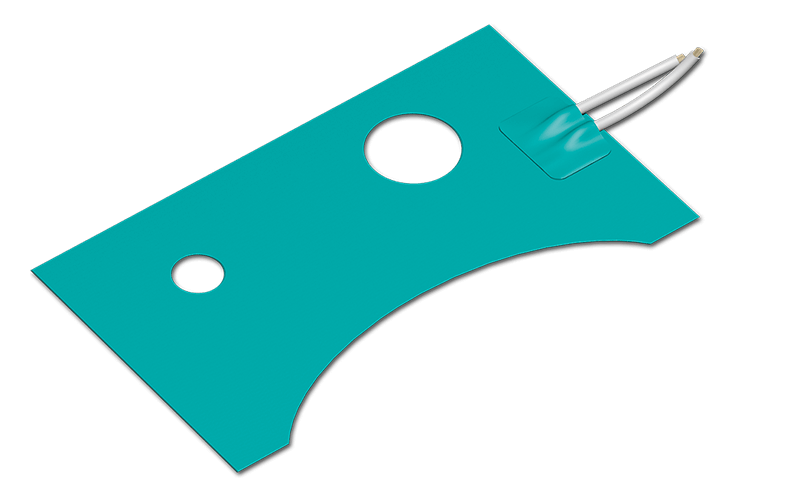

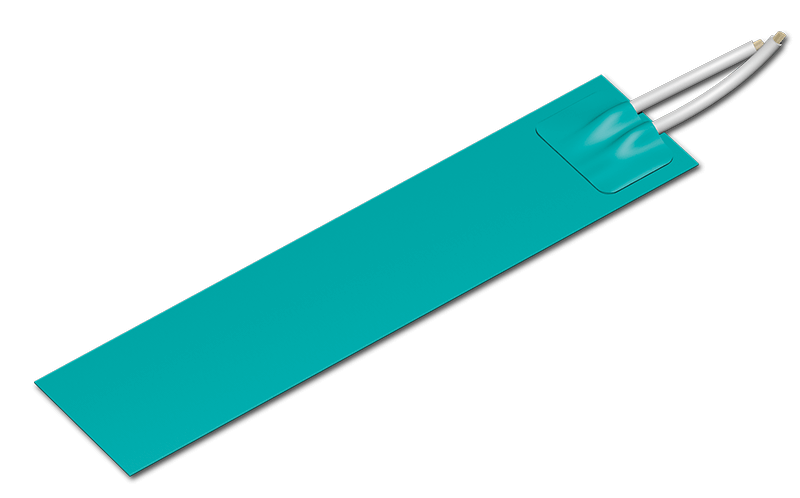

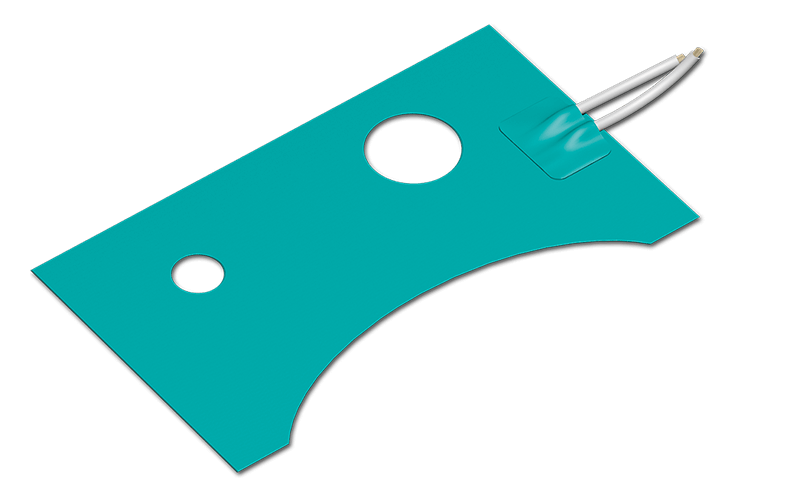

Flexible heating mats and tapes for homogeneous surface temperature control

With hotform silicone heating elements, you defrost, heat and heat flat as well as round, curved and circumferential surfaces. They are ultra-flat, lightweight and flexible. As mats, tapes or customized molded parts, hotform silicone heating elements can be very easily fixed to surfaces and are also suitable for integration into sandwich constructions and multilayer systems.

hotform silicone heating elements are designed for a wide temperature range from ‑60 °C to +270 °C and can be controlled with high control accuracy in a time- and temperature-oriented manner. They ensure the functional and operational reliability of technical systems and minimize the effort required for their maintenance and repair.

You receive our hotform silicone heating elements as ready-to-install system components. Size, design and connection type are individually oriented to your specific application.

Fields of application

Telecommunications and antenna technology

Parabolic antenna, flat antenna, panel or rod antenna: Our hotform silicone heating elements can be used for the flat, round, concave and convex surfaces of all types of radio, TV, radio or satellite antennas. They can be used both indoors and outdoors as a stand-alone solution, as a built-in component or as an intermediate layer in sandwich constructions. Depending on the objective, they are used for defrosting (anti-icing) or for heating dishes, reflectors, radiators or housings.

Another major area of application for hotform silicone heating elements in the field of telecommunications and information technology is the heating of control cabinets as well as components of satellite technology, remote data transmission and industrial measurement and control technology.

hotform silicone heating elements are UV-resistant, weatherproof, waterproof to IP 67 and comply with EN 45545 (smoke, fire)

Railroad construction, track and signaling technology

In railroad engineering, hotform silicone heating elements are used, among other things, to heat or defrost doors, steps, entrances, windows, mirrors, seats, floors, cladding as well as fresh and waste water tanks, pipelines and railcar couplings. They are also used to heat traction current collectors and the fronts of railcars. In track and signal technology, they protect mechanical actuators and electrical-electronic switching contacts in railroad tracks, switches, signals and display panels from icing.

hotform silicone heating elements can be installed very easily and flexibly. They are UV-resistant, extremely weatherproof and waterproof to IP 67. They also comply with EN 45545 (fire, smoke) as well as 50264 and EN 50306 (rail vehicles).

Food Technology

In the food industry, hotform silicone heating elements are used both within production and processing (machines, processes) and in preparation (e.g. large kitchens, private consumers) and distribution (e.g. catering, logistics). Depending on the objective, they are used to heat, warm, cook, liquefy, melt, defrost or keep warm liquid, pasty or solid foods.

Typical applications for hotform silicone heating elements in the food sector include waffle irons, hotplates, pipe trace heating systems in chocolate production and hot holding systems in canteen technology.

hotform silicone heating elements are FDA-compliant and can be very easily fixed to the surfaces of systems, equipment, containers and pipelines. They are used in food technology in many thermodynamic and fluidic procedures and processes.