Hydraulic and thermal process visualization

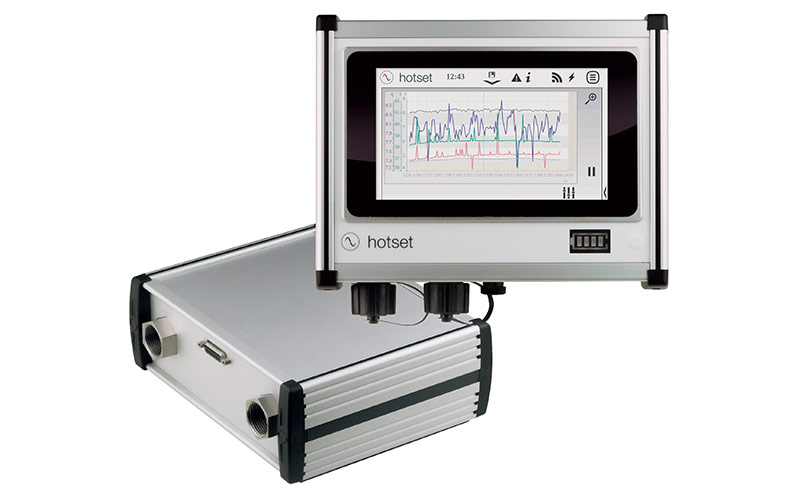

D‑System Data Logger

The D‑System is used for simple in-situ visualization of hydrothermal processes in process water cycles.

In our System Center for Industrial Temperature Control Technology (SIT), which has been in existence since 2020, you will have the opportunity to get to know – and extensively test – our latest innovations in the field of targeted temperature control of molds and process media as well as semi-finished products and products made of plastic.

D‑System – Data logger

hotset’s D‑System is a mobile and flexible measuring device for a quick on-site analysis of the energy balance in technical water cycles. Wherever water is in circulation as a functional medium, the flow rates, temperature curves and pressure differences can be checked and visualized promptly.

The data logger consists of a compact measuring module and a color 7‑inch touch screen – a combination which covers a wide range of applications. You can use it for troubleshooting, fine-tuning fluid power processes, quality assurance, and many other applications which use water as a coolant and heating medium, as a transport and hydraulic fluid, as an operating and drive medium, or as a fuel component.

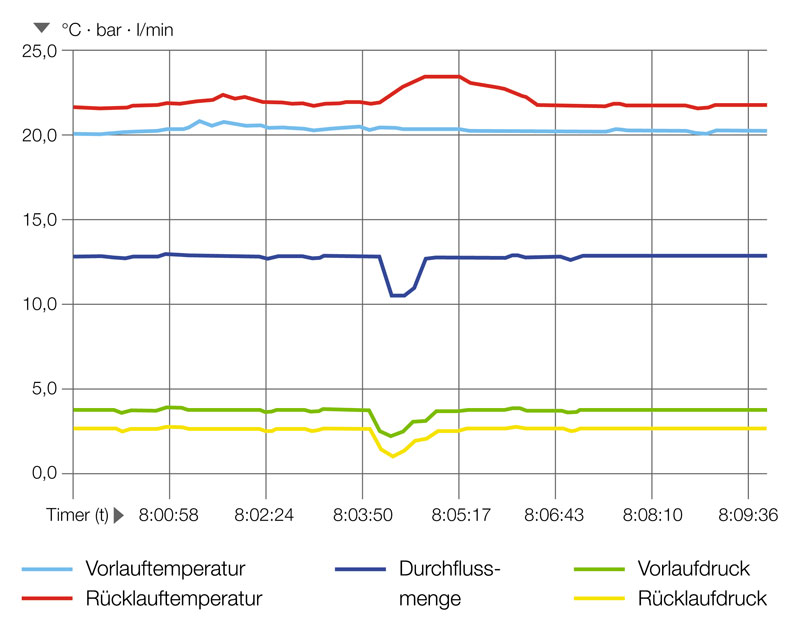

The system provides you with all needed data for qualified evaluations of the energy flows in your water circuits. Its sensors determine the flowing water volume, the supply and return temperature ∆T as well as the supply and return pressure ∆P. Based on this, all relevant progressions that characterize the water circuit of your process or system in terms of energy are calculated and displayed graphically.

With the D‑System, you can store, document and reconcile all recorded information at intervals. W‑LAN and LAN interfaces support both the convenient network connection of the data logger and PC or smartphone access to the visualized measurement data of its touch screen. All processes can be logged and synchronized, and limit violations are also displayed. You can operate your D‑System via 230-volt mains connection or in battery mode.

Instruction manual (video)

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von YouTube.

Mehr erfahren

Process optimization and quality assurance

In the entire field of water fluid technology, the D‑System serves as a flexible measurement and visualization tool for process optimization and quality assurance. Thus, it is used, for example, for checking and designing the water circuits in the temperature control systems of the cavities of injection molds. It can also be used in cold water hydraulics, heating technology or drive technology.

Re-Engineering and Retrofitting

In the context of continuous improvement processes (CIP), hotset’s D‑System can be used for medium- or long-term tracking of the hydrothermal development of water cycles in process plants. During re-engineering or retrofitting, it enables the rapid identification of modernization potentials and the targeted location of parameters to be optimized.

Maintenance and repair

The D‑System can be used for MRO applications (Maintenance, Repairs, Operation) across all industries as a mobile and location-independent service tool. It also proves to be an extremely practical measuring and testing tool for fault detection in the context of predictive monitoring — i.e. preventive maintenance — of fluid technology processes. Thanks to its simple handling and operation, the effort required for the maintenance and repair of water technology circuits can be significantly reduced with the D‑System.