The German family-owned company hotset is one of the leading component suppliers and development service providers in the field of industrial heating technology. Its current portfolio ranges from the production of heating elements and sensors to the realization of complex system products and customized project solutions. Read the interview with company CEO Ralf Schwarzkopf to find out where the company ranks in its 50th year of existence and what its long-term goals are.

Ralf Schwarzkopf: “Based on our growth course to date, we want to establish hotset as a brand for first-class temperature control technology solutions.

Providing exact temperature values at the right moment — under this premise, hotset has been realizing heating elements, thermal sensors and system solutions for temperature control technology for 50 years now. In your opinion, which early developments in the company’s history still shape your actions today?

Schwarzkopf: When my father Eugen Schwarzkopf introduced our first high-performance heating cartridges for use in die casting and plastics technology in 1973, the capital goods sector was just undergoing a change from a request market to a supply market. This meant that suppliers now had to actively approach customers and familiarize themselves with their applications. This meant that suppliers had to actively approach customers and familiarize themselves with their applications. They had to build up their own technology and engineering know-how, acquire cross-industry problem-solving skills and constantly explore new specialist areas. Maintaining flexibility, restructuring one’s own core processes and changing one’s own mindset — these are undoubtedly key factors in hotset’s successful development to this day.

Where in the portfolio is this evident in the here and now?

Schwarzkopf: Today, we cover the entire range from component production and system development to individual customer projects. We are therefore both a supplier and an engineering and value-added partner for customers in a wide range of industries — from plastics technology and foundry engineering to fluid, process and electrical engineering. What began in the early hotset years with the expansion of the range of accessories, the expansion of installation technology and the development of design competencies is continued today in a constantly growing pool of expertise in measurement and control technology, process optimization, energy management, digitization and automation.

How do you manage to implement this range of services in organizational terms?

Schwarzkopf: I like to sum it up in the terms learning, structuring and internationalizing. By the former, I mean in particular the constant acquisition and application of new knowledge in the areas of technology, engineering, qualification and management. Learning processes are important stages in the history of hotset. They were and are the basis for structural modernization and groundbreaking knowledge gains at all levels of the company.

Can you give some practical examples to illustrate this?

Schwarzkopf: In the recent past in particular, we have successfully implemented a large number of structural innovations. I am thinking, for example, of additional engineering and process competencies for the development of innovative products and systems, refined lean management processes in production and administration, increased availability, shorter lead times in order processing, automation of our production, and the introduction of new services. The establishment of SIT, our new system center for industrial temperature control technology, also falls under the heading of learning and structuring for me.

Customer-oriented: At hotset’s System Center for Industrial Temperature Control (SIT), injection molders and mold makers can find out about the performance of the DH system for partial-cycle cavity temperature control, among other things.

And what about the internationalization of the company?

Schwarzkopf: Today, hotset has a global presence — among other things through foreign subsidiaries with their own assembly plants. Soon after the company was founded, my father established the first agencies in Spain, France and Scandinavia. At the beginning of the 1980s, the Hotset Corporation was founded in the USA, followed by branches in Asia, New Zealand, Austria, Turkey, South America and India. Internationalization was given a strong boost in 2001 with the establishment of our plant in Malta and in 2010 with the launch of the independent Hotset America Corporation. 2014 saw the establishment of HIPL India Pvt Ltd, which manufactures our heating cables. The Malta plant has since moved to larger buildings and has been an EU Energy Efficiency Partner since 2016.

You took over the management of the company from your father at the turn of the year 2001…

Schwarzkopf: …right, that was an eventful time. We already had over 100 employees in spiral cartridge production alone, and the development of the hotflex for heating 3D molds and new control equipment was already in full swing. Shortly thereafter, we expanded Malta and put our current main plant in Hueckstraße in Lüdenscheid into operation.

How did the generation change take place at the top of the company?

Schwarzkopf: There were a few disputes between father and son, but in contrast to other companies, the transition from the first generation of founders to the second generation of bosses was quite successful for us. Especially since the flow production for the HHP and LHT cartridge heaters introduced under my father and a modern PPS system ensured high productivity and availability. In addition, our developers were able to implement further innovations year after year — for example, new hotspring variants, new hotcontrol control units, or even new hotcast gating nozzles for magnesium die casting. All these solutions are still part of our portfolio today and have set standards in the industry in many places. From the very beginning, my primary goals were to strengthen the innovative power of the company, to further increase our quality level, to expand hotset’s engineering competencies, and to push ahead with internationalization.

What competitive strengths would you currently attribute to hotset?

Schwarzkopf: As a manufacturer of components for industrial heating technology — here we are talking about temperature control channels, heating elements, resistance thermometers and thermocouples, for example — we score points with a large selection of quality products for many areas of application. As a developer of flexible system solutions, we offer a growing range of innovative and energy-saving process solutions with the P‑System heating plates, the D‑System data logger and the DH-System for the highly dynamic temperature control of injection molds. And in the project business, we take over entire value chains for our customers ¬- such as control cabinet assembly. From a technological point of view, we have positioned ourselves strongly, and in our development work we can convince with high innovative strength and short innovation cycles.

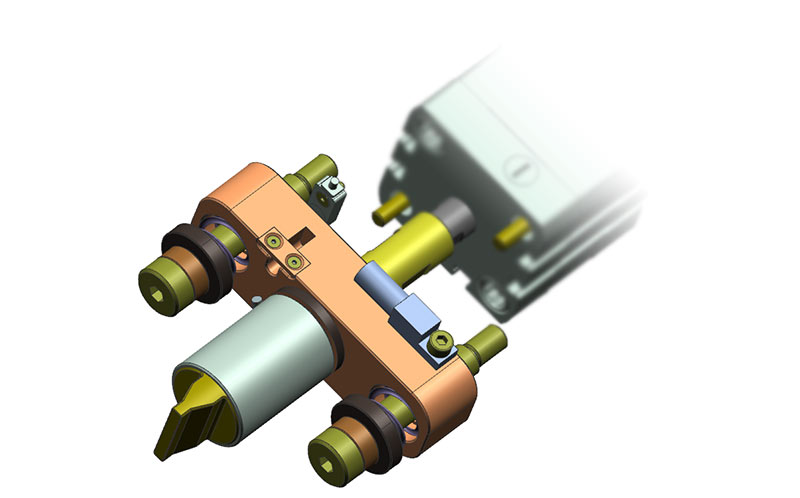

Dynamic temperature control in injection molding: Compared to the variothermal method, the DH system from hotset is more effective and energy-saving. It operates at a fast heating rate of up to 60 Kelvin per second, acts specifically only on a minimum mass and uses 50 times less energy in the heating phase.

Versatile: With its mobile D‑System HT for monitoring fluids at temperatures of up to 180° C, hotset offers a flexible measuring device for in-situ analysis of the energy balance of water cycles.

As a technology partner, hotset today assumes responsibility for complete value chains for its customers in the project business ¬- such as control cabinet assembly.

Where do you see hotset in five to ten years?

Schwarzkopf: I have clear ideas about that. Based on our growth to date, we want to establish hotset as a brand for first-class solutions in temperature control technology. And not only for industrial heating and cooling technology, but also for refrigeration and cooling technology. Both as a supplier and as a system developer and project partner, we will continue to increase our availability, our customizing competencies and our quality level. In doing so, we are driven by three major guiding principles: First, to improve the customer’s added value. Second, to support our customers’ future-proof transformation processes — such as the switch from gas to electric heat or the achievement of CO2 neutrality. And thirdly, to internationalize the realization of new components more strongly by consistently involving our foreign subsidiaries so that we can implement important innovations even faster.

Mr. Schwarzkopf, thank you for the interview.