Company CEO Ralf Schwarzkopf: “The guiding principle of our project business is the comprehensive notion of technologically oriented outsourcing, in which hotset assumes overall responsibility for entire value chains.”

In addition to the rapid delivery of heating elements and thermal sensors and the realization of innovative system solutions, customer-oriented project business is one of the high-growth disciplines in hotset’s portfolio. In this area, the company acts as an outsourcing partner and assumes responsibility for entire value chains of its customers. In the interview, company boss Ralf Schwarzkopf explains which services hotset’s project business covers and which further expansion stages are targeted here.

Mr. Schwarzkopf, what does it mean in concrete terms when you talk about “project business”?

Schwarzkopf: In the project business, our central concern is to relieve our customers of complete production and assembly processes. Behind this is the very comprehensive idea of a technologically oriented outsourcing, where hotset takes over the overall responsibility for entire value chains. This gives the client new freedom, which he can use in a variety of ways: To expand its core business, to optimize its in-house processes or to introduce lean manufacturing structures — to name just a few possible goals.

In the meantime, are there any practiced examples of this type of value-added outsourcing?

Schwarzkopf: But yes. We have set this line of business about four years ago on the track and operate since then for quite a few customers in various industries individually coordinated process chains of prefabrication and finishing. For example, for a manufacturer of gas measuring equipment. We manufacture temperature sensor system solutions in a production line set up especially for him — including installation, housing configuration, quality assurance and packaging. The customer has placed this process of its component production entirely in our hands. We have implemented a complete assembly line for a renowned manufacturer of control cabinets; here, too, we are responsible for a large section of the value chain. Currently, we are in talks with companies from the areas of fuel cell technology and e‑mobility — here it is also about the development of manufacturing structures for thermodynamic solutions.

Is your outsourcing basically always connected with hotset’s own core business?

Schwarzkopf: Our motto is “controlled energy flow”; in this respect, our outsourcing projects are also primarily concerned with tasks relating to industrial thermodynamics and thermosensor technology — but in the broadest sense. After all, the problem of making a defined temperature available at a precise point in time or over a limited area — for heating, cooling or temperature control — plays a central role in many industries. In toolmaking as well as in surface technology or in plastics processing, in packaging technology, in food technology, in foundry engineering and many other areas.

Which principles or guidelines does hotset follow when setting up the value chains?

Schwarzkopf: In fact, the customer’s objectives naturally determine how we organize and structure the process chains. From our side, however, we always bring authoritative aspects of process optimization, efficiency improvement and resource conservation. Frequently, the consulting discussions, feasibility and value analyses from our system development department form the point of departure for an outsourcing project. It is not uncommon for the development work and prototyping to lead to an implementation phase, at the heart of which is the realization of the customer-specific system solution, assembly or special design. At this point, the question arises whether the customer should build up its own production capacities or whether the transfer of defined value chains to hotset is more advantageous.

.

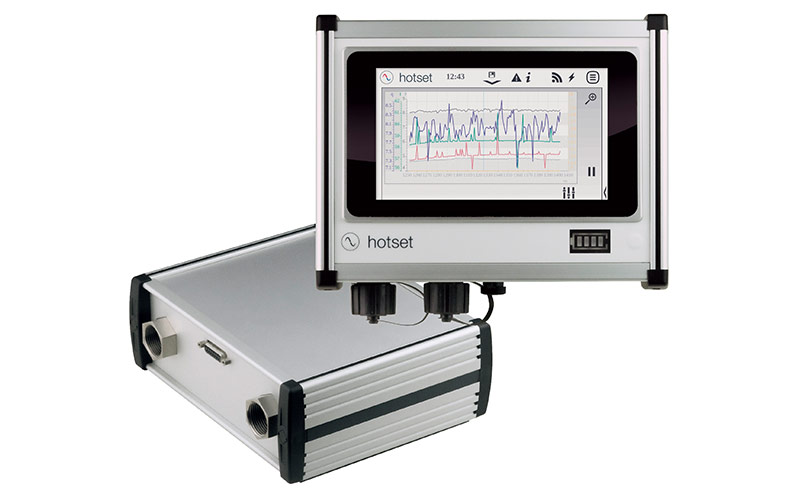

Flexible and decentralized: Under the name D‑System, hotset presented its new data logger for in-situ recording of fluidic processes in the temperature control circuits of injection molds at K 2019 in Düsseldorf.

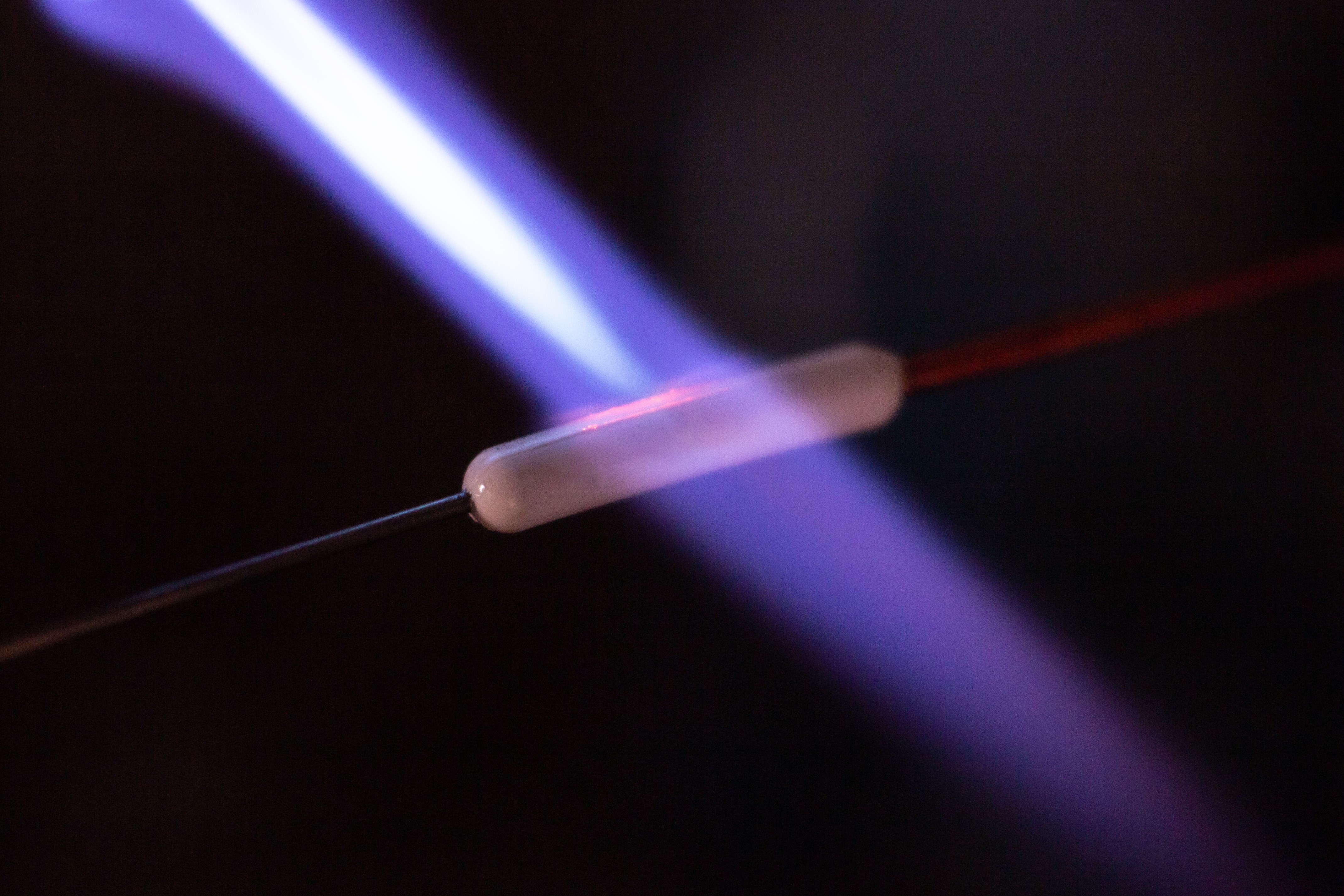

With the new connecting sleeve HPS 400, hotset has recently expanded the range of thermocouples and resistance thermometers in its hotcontrol product line. Thanks to its heat resistance of up to 400° C and a tensile strength of more than 120 N, it gives the sensors very good thermal and mechanical stability at the transition from the measuring tip to the compensating leads.

Successful system solution: While a weld line remains visible in the conventionally injection molded housing part (left) and the thin-walled passage is “torn,” the housing molded with the Z‑system (right) shows a flawless surface and the thin-walled passage could be realized without any problems.

Where does hotset draw its expertise for setting up production and assembly lines?

Schwarzkopf: The technological basis for this is 46 years of experience in the development and manufacture of ready-to-install heating elements and system components, including the appropriate sensor, regulation and control peripherals for many different key areas of industry. Based on this, we are today in a position to call up interdisciplinary know-how across all industries and to incorporate it into the structure of customer-specific value chains. Added to this is the international interaction of hotset and its subsidiaries in America, China, Singapore, India and Malta. If one of our subsidiaries generates a customer project, problem solving and engineering take place at the hotset headquarters in Lüdenscheid. The technical realization againrum takes place locally in customer proximity — if necessary then evenly including the establishment of production and assembly lines under our direction.

Where are then de facto the borders of the creation of value outsourcing of hotset?

Schwarzkopf: In principle, we have an open ear for all the wishes and ideas of our customers, and from a process point of view, we cover the entire chain from procurement and incoming goods inspection to the warehousing of the components required for production to manufacturing or assembly. Quality assurance and delivery or “just-in-time provision” are also part of the range of services offered by the project business. Technologically speaking, value-added outsourcing should also be in touch with our core competencies, i.e. heating technology, sensor technology, control technology, electrical engineering or installation technology.

And how do you ensure that the whole thing is also economically worthwhile for the customer?

Schwarzkopf: Well, that’s ultimately the whole point. Our project business has the goal of conserving the customer’s capital commitment. To ensure this, the client has unrestricted insight into the cost calculation of the entire outsourcing project at all times. We attach great importance to this transparency. For us, it is an indispensable element of a trusting collaboration.

Mr. Schwarzkopf, thank you for the interview

.