Energy-efficient, mass-optimized and very precisely controllable: complex P‑System heating plate by hotset for large surface heating.

In the course of the current debate on energy prices, many manufacturing companies are currently changing their generation of process heat. Where gas-fired systems dominated the scene for decades, electric direct heating systems are now increasingly taking over. The thermodynamics specialist hotset supports this change with energy-efficient high-tech solutions that can be intelligently controlled and can significantly improve the sustainability of many production processes. A vivid example of this is the use of the German company’s heating plate systems, which are designed to suit customers and applications.

The thermodynamics and temperature control engineers at hotset currently have their hands full. As many manufacturing companies are questioning their previously gas- or steam-based process heat generation due to the increasing pressure on energy prices, they are also turning to the possibilities of modern electric heating and cooling technology. hotset is an extremely attractive technology partner in this field, not only with its wide range of temperature control channels, heating elements and sensors, but above all with its thermodynamic system solutions. “The K trade fair showed that in particular our P‑Systems have a high relevance for the energy technology transition of companies. These are customer-specific and individually designed hot plate solutions that can be used to heat or warm surfaces homogeneously, precisely and energy-efficiently”, says hotset sales manager and proxy holder Sven Braatz. hotset had originally developed these direct heating systems for thermal process control in processing of plastic and packaging films. Meanwhile, however, thanks to their flexibility, speed and control accuracy, they also make a decisive contribution to the realization of resource-saving CO2-reduced and climate-neutral value chains in numerous other manufacturing areas. For example, they make it possible to move away from gas-based energy supplies in bonding and vulcanization technology, woodworking, the production of composite materials and large-area molds, as well as in glass technology, fluid technology and media guidance.

Sven Braatz: “Our P‑Systems enable intelligent provision of process heat in many applications of manufacturing, joining, shaping and surface technology. They often prove to be significantly more targeted and energy-efficient than gas firing.”

Direct, accurate and efficient

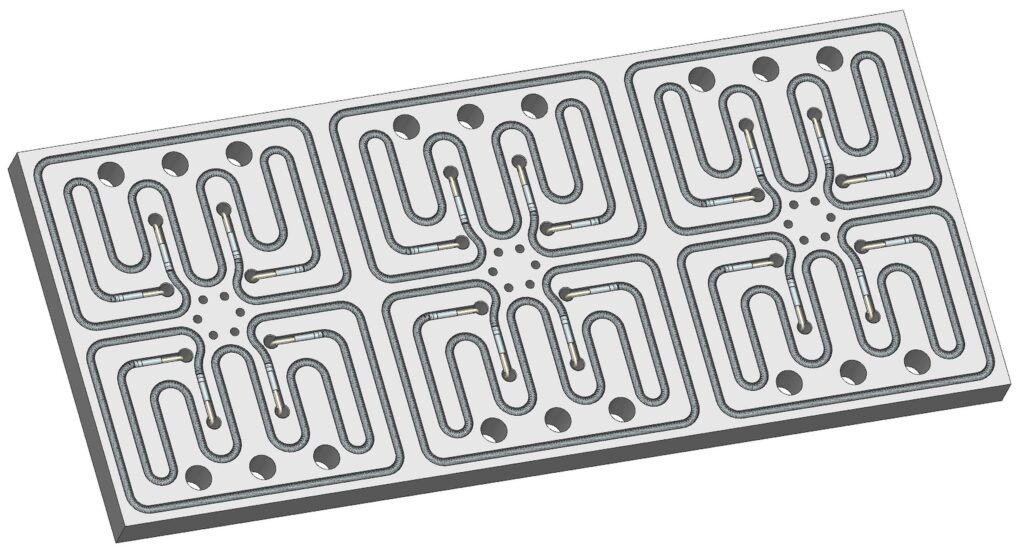

Under the umbrella term “P‑System”, hotset implements a whole range of modern hot plate solutions, the dimensions, design and configuration of which are always optimally matched to the individual specifications of customers in mechanical and plant engineering. “Deep-drawing plastic trays, after all, places completely different demands on the design and performance of heating plate systems than their use in vulcanizing presses, bonding processes or other processes. Based on our expertise, the competencies of our engineering and our flexible manufacturing organization, we can implement the ideal P‑system solution for almost any surface temperature control task”, emphasizes Sven Braatz. A major strength of the hotset heating plates is the very precisely adjustable temperature control. It ensures that the temperature is distributed and transferred to the surfaces of molds, workpieces and materials with a very high degree of homogeneity. This offers the user a high level of process reliability. A decisive factor for the high energy efficiency is added by the fact that the hotset engineering has implemented a consistent reduction of the heated masses in the design of the heating plates.

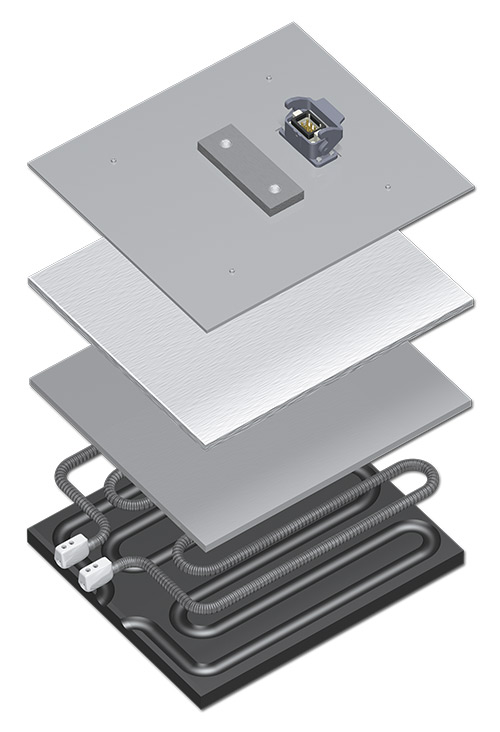

The customization of the P‑System surface heating plates by hotset ranges from the design of the heat transfer plate to the selection of heating elements, insulation plates and installation space plates to the design of the cover plate.

System change made to measure

Depending on the design, the P‑Systems from hotset can be operated on supply voltages from 12 to 400 volts and offer surface heating outputs of up to several kilowatts. They are provided as plug-in solutions ready for assembly, including all functional components for integration in existing production structures – also in feedback systems and control engineering. Customization is not only at system level, but encompasses all individual power modules. In concrete terms, this means that a heating plate can be round, rectangular or have any other basic shape, and its dimensions can reach several square meters. The design of the insulating panel, as well as the design of any additional installation space plates and the cover with the plug-in contacts and fastening elements for installation, also follow the wishes of the customers. In the selection of heating elements – a central aspect in the individualization of the heating plates – the flexible tubular heating elements of the hotflex product line in particular play a decisive role. They can be freely laid by hand in any direction and enable contour-specific and precisely targeted temperature control. “Furthermore, we can install sensors to protect against overtemperatures, and in addition to antistatic, non-stick and aseptic coatings for the plate surfaces, we also offer coatings for increased wear and corrosion protection, as well as the option of individual structuring and contouring. Last, but not least, we are also able to implement special requirements for sliding behavior, surface hardness, chemical resistance, electrical conductivity and ease of cleaning”, says Sven Braatz.

Time to change – shortage as a chance

Despite the limited room for maneuver left to medium-sized industrial companies by the gas shortage and the resulting price pressure, more and more companies are seeing the current situation as an opportunity to switch to alternative energies and climate-neutral processes. They are receiving financial support from public funding programs that are currently being launched in many places. They make it easier especially for small and medium-sized companies to set up resource-conserving and sustainable production environments that reduce CO2 emissions and lower the companies’ ecological footprint. “At operational level, it’s then a matter of concrete technological implementation. This is where, among other things, innovative heating and temperature control solutions are then called for, such as our P‑System for intelligent provision of process heat in manufacturing, joining, shaping and surface technology applications. They often prove to be significantly more targeted and energy-efficient than gas firing”, says Sven Braatz.